Chint NXC series small contactors

Product description

The Chint NXC series small contactors have a novel appearance and a compact structure, with a variety of advantages and characteristics. The following is the relevant introduction:

The Chint NXC series small contactors have a novel appearance and a compact structure, with a variety of advantages and characteristics. The following is the relevant introduction:

- **Purpose and Standards**: It is mainly used for frequently starting and controlling AC motors, remotely connecting and disconnecting circuits, and can form an electromagnetic starter together with an appropriate thermal overload relay. The applicable standards include GB/T 14048.1/IEC 60947 - 1, GB/T 14048.4/IEC 60947 - 4 - 1, GB/T 14048.5/IEC 60947 - 5 - 1, and GB 21518.

- **Working Environment and Current**: The working environment temperature is from -35°C to 70°C, and the rated working current Ie is from 6A to 630A.Chint NXR series thermal overload relays price*:

- **Product Advantages**: Adopting a 3D structural motion simulation system makes the structural coordination closer; using new low-resistance contact materials provides stronger anti-fusion welding properties; through automated production, the product consistency has been improved.CHINT circuit breaker price*:

- **Contact Configuration**: For example, models such as NXC - 225 and NXC - 630 usually have 3 normally open (NO) main contacts, and the auxiliary contacts have different configurations such as 2NO + 2NC.CHINT surge protector price*:

- **Mechanical Emergency Start Device**: The NXCQ AC contactor (mechanical emergency start device) cooperates with the Kunlun NXC series AC contactor products to form emergency start devices of different current ratings, which are suitable for the start-stop control of motors with a rated working voltage of 400V and a rated working current of 400A and below, and can meet the needs of different scenarios such as the fire water supply system.

The working principle of the Chint NXC contactor is based on the effects of electromagnetic induction and the spring mechanism, and is mainly composed of parts such as the electromagnetic system, the contact system, and the arc extinguishing device. The details are as follows:Schneider Circuit Breakers

- **Electromagnetic System**: When the electromagnetic coil of the contactor is energized, a current will be generated in the coil, thus creating a magnetic field. This magnetic field will make the iron core generate electromagnetic suction force, attracting the armature to move. The armature is connected to the moving contact. Under the action of the electromagnetic suction force, the armature drives the moving contact to move towards the stationary contact.

- **Contact System**: When the moving contact touches the stationary contact, the circuit is connected, and the load (such as motors, lamps, etc.) starts to work. At this time, the electromagnetic suction force will keep the armature and the contacts in the closed state to maintain the conduction of the circuit. When the electromagnetic coil is de-energized, the magnetic field disappears, and the electromagnetic suction force also disappears. Under the action of the contact spring and the return spring, the armature and the moving contact will return to their initial positions, the moving contact separates from the stationary contact, the circuit is cut off, and the load stops working.

- **Arc Extinguishing Device**: At the moment when the contacts break the circuit, an arc will be generated. The arc will cause the contacts to be eroded, reducing the service life of the contacts, and may even cause faults such as interphase short circuits. The Chint NXC contactor usually uses arc extinguishing devices such as arc extinguishing covers to extinguish the arc. The arc extinguishing cover is generally made of arc-resistant materials, and its structure can make the arc cool down and elongate rapidly inside the arc extinguishing cover, thus accelerating the extinguishing of the arc and protecting the safety of the contacts and the circuit.

I. Core Technical Parameters

1. **Rated Current and Voltage**

- **Current Range**: It covers from 6A to 630A (for example, NXC-06M is 6A, and NXC-630 is 630A), and is suitable for motors with a power of 0.37kW to 315kW.

- **Voltage Compatibility**: The main circuit supports AC220V to 690V, and the coil voltage can be selected as AC24V, 36V, 110V, 220V, 380V or DC24V, 48V, 110V, 220V, and is compatible with a frequency of 50/60Hz.

- **Duty Cycle**: It is suitable for usage categories such as AC-3 (starting and running of squirrel-cage motors) and AC-4 (frequent starting, plugging braking of motors), and the electrical life can reach 600,000 times (AC-3).

2. **Structural Design**

- **Arc Extinguishing Technology**: Adopting a double-break direct-acting contact structure, the ceramic arc extinguishing chamber can withstand a peak short-circuit current of 100kA, with strong breaking capacity.

- **Installation Method**: It supports installation on 35mm or 75mm standard snap rails. The wiring terminals are equipped with insulating covers, and the protection level is IP20 (IP55 is optional for some models).

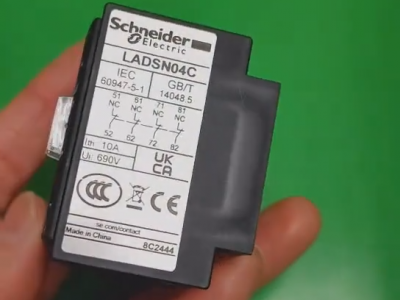

- **Auxiliary Contacts**: Standard configuration is 1 normally open and 1 normally closed (06M-100A) or 2 normally open and 2 normally closed (120A-630A), and an F4-22 auxiliary contact group can be expanded (adding two pairs of contacts).

3. **Environmental Adaptability**

- **Temperature Range**: From -35°C to +70°C (extreme working temperature), and the normal working temperature is from -5°C to +40°C.

- **Altitude and Humidity**: Altitude ≤ 2000m, humidity ≤ 90% (at 20°C), pollution degree is grade 3, and it is suitable for humid and dusty environments.

- **Certification**: It has passed CCC and CE certifications and complies with standards such as IEC 60947-4-1 and GB/T 14048.4.

II. Functional Characteristics and Application Scenarios

1. **Typical Applications**

- **Industrial Control**: Start-stop control of equipment such as fans, water pumps, and conveyor belts, and form an electromagnetic starter together with a thermal relay.

- **Commercial and Building**: Central air conditioning, lighting systems, elevator control, supporting star-delta starting and reversible control.

- **New Energy Field**: Switching control at the output end of photovoltaic inverters to suppress harmonic interference.

2. **Adaptation to Special Scenarios**

- **High Altitude**: It has passed the certification for an altitude of 1500 meters and does not need to be derated for use.

- **Fire Emergency**: The NXCQ series (mechanical emergency start device) complies with the GB 50974 standard and is suitable for the control of fire pumps.

- **Harsh Environment**: Models with an IP55 protection level can be used in water treatment plants and coastal facilities.

III. Selection and Usage Suggestions

1. **Calculation of Key Parameters**

- **Selection of Rated Current**: Select it according to 1.2-1.5 times the rated current of the motor (for example, select NXC-18 for a 380V/7.5kW motor).

- **Coil Voltage Matching**: Give priority to selecting a voltage consistent with the control system (for example, if the PLC outputs 24V, a DC24V coil needs to be customized).

- **Duty Cycle Adaptation**: For AC-4 type loads (such as cranes), a higher current rating needs to be selected (for example, replace NXC-22 with NXC-32).

2. **Installation Precautions**

- **Wiring Torque**: An 8-10N·m torque should be applied to the main contact terminals (use a torque wrench) to avoid poor contact.

- **Phase Sequence Requirements**: For reversible contactors (models containing "N"), the wiring should be corresponding to the phase sequence to prevent the motor from reversing.

- **Heat Dissipation Spacing**: Maintain a spacing of more than 20mm between adjacent contactors to avoid excessive temperature rise.

3. **Accessory Expansion**

- **Auxiliary Functions**: An LA1-D11 indicator light module, an F4-22 auxiliary contact group, or a time relay can be installed.

- **Protection Devices**: Match with the NXR series thermal relay or NSD1 servo controller to achieve overload and phase loss protection.

IV. Maintenance and Fault Troubleshooting

1. **Preventive Maintenance**

- **Quarterly Inspection**: Clean the dust in the arc extinguishing chamber and measure the contact resistance of the main contacts (≤50mΩ).

- **Annual Verification**: Use a contactor test bench to verify the action time (closing ≤ 30ms, releasing ≤ 50ms).

- **Life Management**: Estimate the remaining life through the number of actions of the auxiliary contacts (it is recommended to replace it after 500,000 actions).

2. **Common Fault Handling**

- **Contact Adhesion**: Check whether the load current exceeds the limit, or whether the arc extinguishing chamber is carbonized (the contact assembly needs to be replaced).

- **Coil Burnout**: Measure the insulation resistance (≥10MΩ) and check the stability of the control voltage.

- **False Operation**: Check for electromagnetic interference, or add a surge suppressor (such as an RC absorption circuit).

V. Comparison with Competitors

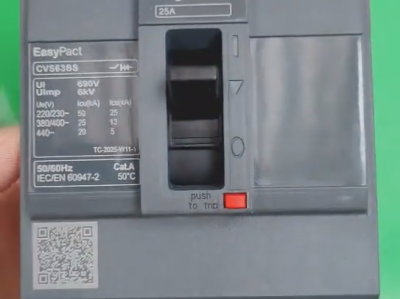

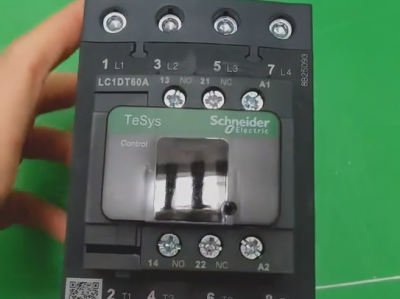

| Characteristics | NXC Series | ABB T9 Series | Schneider LC1D Series |

| Electrical Life (in ten thousands of times) | 60 (AC-3) | 50 | 45 |

| Installation Space | 90mm (63A) | 110mm | 100mm |

| Price (in US dollars) | 30-150 | 40-200 | 35-180 |

| Environmental Adaptability | -35℃~+70℃ | -25℃~+60℃ | -25℃~+60℃ |

VI. Procurement and Service Support

1. **Authorized Dealers**

- **Middle East**: hebei china Electric CO.,LTD (WhatsApp:86-13811255435).

2. **Certification and Compliance**

- **International Certification**: CE (Certificate No.: CHNT-CE-003621), RoHS (complies with EU directives).

- **Middle East Standards**: It meets the requirements of the GSO Gulf Standardization Organization and can provide SASO certification documents.

3. **After-sales Service**

- **Warranty Policy**: 18-month warranty, and paid maintenance is required for man-made damage.

- **Technical Support**: For bulk purchases (≥500 units), free on-site technical guidance can be applied for.

If you need to further understand the price, delivery time, or customized solutions (such as DC coils, IP55 protection), you can directly contact the Chint regional sales manager (email: sales000888@gmail.com). For special requirements (such as explosion-proof, marine use), non-standard customized services can be provided.