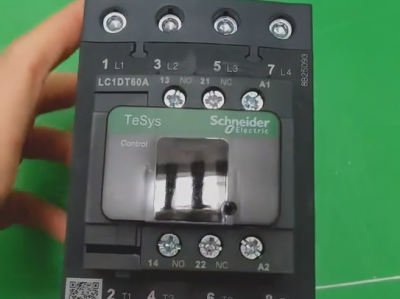

Schneider LC1E400 Contactor

Product description

Product Positioning

The Schneider LC1E400 is a 400A high-current AC contactor belonging to the EasyPact TVS series. Specifically designed for industrial applications, it is used to control electric motors, lighting equipment, and other high-power loads.

Core Parameters

| Parameter | Specification |

| Rated Operating Current | 400A (AC-3 Duty Cycle, ≤55°C) |

| Rated Insulation Voltage | 690V AC 50/60Hz |

| Conventional Heating Current | 500A (≤40°C) |

| Control Coil Voltage | Multiple options available: 110V/220V/380V/415V AC 50/60Hz |

| Main Contact Configuration | Standard type: 3P (3 Normally Open/3NO); 4P (4 Normally Open/4NO) version also available (LC1E40004 series) |

| Maximum Operating Frequency | 2400 operations per hour (≤55°C) |

| Mechanical Life | 4 million operations |

| Electrical Life | AC-3 Duty Cycle: ≥100,000 operations |

| Protection Degree (IP Rating) | IP00 (No Protection) or IP20 (Finger-proof Protection) |

| Applicable Ambient Temperature | 5~55°C; Storage Temperature: -60~80°C |

| Weight | Approximately 9.1kg |

| Dimensions (Width × Height × Depth) | 213×375×219mm |

Duty Cycles and Applications

Main Duty Cycles:

- AC-3: Used for starting and stopping squirrel-cage motors, which is the most common industrial application.

- AC-1: Used for controlling non-inductive or slightly inductive loads, such as resistance heating equipment.

Typical Application Scenarios:

- Motor control systems (power range: 220kW@415V to 280kW@690V)

- Control of AC loads with a power factor ≥0.95

- Industrial automation equipment

- Master switch control for lighting systems

- Other industrial applications requiring high-current switching

Technical Features

Performance Advantages:

- High making and breaking capacity: Capable of withstanding a making current of 4000A and a breaking current of 3200A (440V AC)

- Short-time withstand current: 3600A (≤40°C, 10 seconds), enhancing system reliability

- Wide voltage operating range: The control coil operates stably within 85%~110% of the rated voltage, does not actuate below 70%, and releases reliably within 35%~50%

- Low power consumption design: Only 15VA required in the holding state, reducing energy consumption

- High anti-interference capability: Withstands 8kV impulse voltage, suitable for harsh industrial environments

Structural Features:

- Two installation methods: base mounting or DIN rail mounting, facilitating on-site deployment

- Main circuit wiring: Can connect 2×150mm² cables or 30×5mm copper busbars, with a tightening torque of 35N·m

- Control circuit: Bolt-fastened terminals, capable of connecting 1~4mm² wires, with a torque of 1.2N·m

- Modular design, allowing addition of accessories such as auxiliary contacts and overload protection

Model Coding Explanation

LC1E400X7:

- LC1: Standard prefix for Schneider contactors

- E: EasyPact TVS series

- 400: Rated current of 400A

- X: Coil voltage code

- F: 110V AC 50/60Hz

- M: 220V AC 50/60Hz

- Q: 380V AC 50/60Hz

- N: 415V AC 50/60Hz

- 7: Suffix, indicating standard type (50/60Hz)

Note: The LC1E40004 series is a 4-pole version (4NO) with a rated current of 60A (AC-1), mainly used in special control circuits.

Application Recommendations

1. -Selection Key Points: Choose the appropriate duty cycle based on the load type (AC-3 for motor control, AC-1 for resistive loads)

2. Environmental Considerations: The installation location should be well-ventilated, with an ambient temperature not exceeding 55°C

3. Supporting Protection: It is recommended to use it with appropriate overload protection devices (such as thermal relays) to protect the motor and the contactor itself

4. Cable Selection: For the main circuit, select cables with sufficient cross-sectional area (≥150mm²) to ensure low-impedance connection

5. Maintenance Cycle: Regularly inspect the contact status; a comprehensive inspection and cleaning at least once a year is recommended

Summary

The Schneider LC1E400 is a reliable and efficient industrial-grade contactor. With its 400A high-current handling capacity and robust design, it has become an ideal choice for motor control and high-power load management in various industrial applications. For more detailed technical parameters or special application solutions, it is recommended to refer to the official Schneider Electric manual or