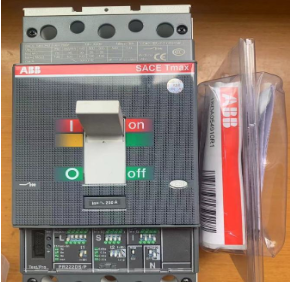

ABB-MCCB-XT2S160-TMD25-FF-3P

Product description

The ABB-MCCB-XT2S160-TMD25-FF-3P is a **Molded Case Circuit Breaker (MCCB)** designed for low-voltage electrical systems, specifically tailored for industrial and commercial applications requiring reliable overload and short-circuit protection. Below is a detailed breakdown of its specifications, applications, and purchasing information:

The ABB-MCCB-XT2S160-TMD25-FF-3P is a **Molded Case Circuit Breaker (MCCB)** designed for low-voltage electrical systems, specifically tailored for industrial and commercial applications requiring reliable overload and short-circuit protection. Below is a detailed breakdown of its specifications, applications, and purchasing information:

1. Product Overview*

- **Series**: Tmax XT (High-performance series with compact design)

- **Frame Size**: XT2S160 (160A frame rating)

- **Trip Unit**: TMD25 (Thermal-Magnetic trip with adjustable thermal setting and fixed magnetic setting)

- **Rated Current**: 25A ABB-MCB-SH201-D20

- **Poles**: 3P (Three-phase)

- **Termination**: FF (Fixed Front-mounting terminals)

- **Certifications**: CE, UL, CSA (varies by region)

2. Key Features*ABB-S3N250 Circuit Breaker*

- **Thermal-Magnetic Protection*ABB Molded Case Circuit Breaker T2N160TMD630FF3P*:

- **Thermal Trip**: Protects against overloads by sensing gradual current increases.

- **Magnetic Trip**: Instantaneous response to short circuits (typically 10x In).

- **Adjustable Settings**:

- Thermal setting (Ir) can be adjusted from 0.7 to 1x In (17.5A to 25A).

- Magnetic setting (Im) is fixed at 10x In (250A).

- **High Breaking Capacity**:

- Up to 50kA at 400V AC (varies by version; check the datasheet for exact values).

- **Compact Design**: Fits standard DIN rails for easy installation in switchgear panels.

- **Wide Voltage Range**: Suitable for 240V to 690V AC systems.

4. Applications**

- **Industrial Machinery**: Motors, pumps, and conveyor systems.

- **Commercial Buildings**: HVAC systems, lighting panels, and distribution boards.

- **Renewable Energy**: Solar inverters and wind turbine control systems.

- **Critical Infrastructure**: Hospitals, data centers, and manufacturing plants.

5. Purchasing Information**

Authorized Distributors**

- **Global**: ABB’s official website provides a distributor locator tool.

- **North America**:

- **USA**: Contact ABB’s local sales office in California or authorized partners like hebei china Electric

- **Canada**: [ABB Canada].

- **Europe/Asia**: Regional distributors are listed on ABB’s regional websites.

Product Availability**

- **Lead Times**: Typically 2–4 weeks for standard orders. Expedited shipping may be available.

- **Part Number**: Ensure the exact model is specified (e.g., 10138218 for XT2S160 LSI R25 FF 3P; check ABB’s catalog for your region).

Documentation**

- **Datasheet**: Available on ABB’s website (search for "XT2S160 TMD25 FF 3P").

- **Installation Manual**: Includes wiring diagrams and torque specifications.

6. Compatibility and Alternatives**

- **Alternative Models**:

- For higher breaking capacity: XT2H160 (70kA).

- For adjustable magnetic settings: XT2S160 TMA (Thermal-Magnetic with adjustable Im).

- **Accessories**:

- Shunt trip, undervoltage release, auxiliary contacts, and communication modules (e.g., Profibus).

7. Technical Support**

- **ABB Customer Service**: (USA) or regional support lines.

- **Online Resources**: ABB’s [customer portal] offers technical documents, FAQs, and troubleshooting guides.

8. Compliance**

- **Standards**: IEC 60947-2, UL 489, CSA C22.2 No. 5.

- **Safety Features**: Arc flash protection, short-circuit isolation, and mechanical interlocks.

9. Pricing**

- **Approximate Cost**: $200–$350 USD (varies by region and distributor).

- **Bulk Orders**: Discounts may apply for large quantities.

10. Replacement and Maintenance**

- **Lifespan**: Typically 10–15 years under normal operating conditions.

- **Maintenance**: Regular inspection for wear, corrosion, and loose connections.

For immediate assistance with ordering or technical queries, contact ABB’s dedicated sales team or your local distributor. Provide the full model number (**ABB-MCCB-XT2S160-TMD25-FF-3P**) to ensure accuracy.

Can you provide more details about the ABB-MCCB-XT2S160-TMD25-FF-3P product?

Here’s an in-depth technical breakdown of the **ABB-MCCB-XT2S160-TMD25-FF-3P** Molded Case Circuit Breaker (MCCB), including critical specifications, advanced features, and practical insights for industrial applications:

1. Core Technical Specifications**

| Parameter | Value |

| Rated Voltage (Ue) | 400V AC (standard), 690V AC max |

| Rated Current (In) | 25A (adjustable via thermal setting: 17.5–25A) |

| Breaking Capacity (Icu) | 50kA at 400V AC7 |

| Short-Circuit Protection | Instantaneous magnetic trip at 10×In (250A)3 |

| Thermal Trip Curve | C-type (5–10×In for overload protection)3 |

| Mechanical Life | 20,000 operations |

| Weight | ~2.5 kg |

2. Advanced Functional Features**

a. Trip Unit Design**

- **TMD25**:

- **Thermal Element**: Bimetallic strip for overload protection (adjustable Ir = 0.7–1×In).

- **Magnetic Element**: Fixed instantaneous trip at 10×In (250A) for short-circuit protection.

- **Trip Curve**: Follows C-type characteristics, suitable for inductive loads like motors and transformers.

*b. Construction**

- **Arc Chute Technology**:

- Multi-chamber arc extinguishing system reduces arcing time and improves safety.

- Rated for 50kA short-circuit breaking capacity.

- **Contact Material**: Silver-tungsten alloy for low resistance and high durability.

c. Environmental Resilience**

- **Operating Temperature**: -5°C to +60°C (no derating up to 2000m altitude).

- **Humidity Resistance**: 50% RH at 40°C (non-condensing).

- **Vibration/Shock**: Compliant with IEC 60068-2-6 (vibration) and IEC 60068-2-27 (shock).

3. Application-Specific Use Cases**

a. Motor Control**

- **Typical Setup**:

- Protects 3-phase motors up to 11kW (400V AC).

- Prevents damage from堵转 (locked rotor) currents (e.g., 6×In for induction motors).

- **Motor Starting**:

- Thermal trip delay allows for inrush currents during motor startup (e.g., 6×In for 5–10 seconds).

b. Solar Inverter Protection**

- **DC Link Protection**:

- Suitable for 600V DC systems (derated to 80% of AC rating).

- Coordinates with DC fuses for arc fault protection.

c. Data Center Rack Power**

- **Redundant Power Paths**:

- Used in parallel configurations for N+1 redundancy.

- Trip characteristics prevent nuisance tripping during transient loads.

4. Compatibility & Integration**

a. Accessories**

- **Shunt Trip (SOR-C)**: Remote tripping via 24V DC signal.

- **Auxiliary Contacts (AUX)**: Monitor breaker status (open/closed).

- **Undervoltage Release (UVR)**: Trips when voltage drops below 35% of Ue.

- **Communication Modules**: Profibus DP or Modbus RTU for smart grid integration.

*b. DIN Rail Mounting**

- **35mm DIN Rail**: Compliant with EN 50022.

- **Footprint**: 100mm width × 185mm height × 105mm depth.

5. Compliance & Safety**

- **Certifications**:

- IEC 60947-2 (Industrial MCCBs).

- UL 489 (North America).

- CSA C22.2 No. 5 (Canada).

- **Arc Flash Protection**:

- Class 2 (Limited arc energy) per NFPA 70E.

- Rated for 40 cal/cm² incident energy.

*6. Maintenance & Troubleshooting**

a. Inspection Schedule**

- **Annual Checks**:

- Verify thermal trip settings (Ir).

- Clean contacts and arc chutes.

- **5-Year Overhaul**:

- Replace springs and contact tips.

- Test trip unit accuracy with a circuit breaker analyzer.

b. Common Issues**

| Issue | Cause | Solution |

| Nuisance Tripping | Incorrect Ir setting | Adjust Ir to 1×In. |

| Failure to Trip | Stuck magnetic armature | Lubricate or replace trip unit. |

| Overheating | Loose connections | Tighten terminals to 8–10 N·m. |

7. Competitor Comparison**

| Feature | ABB XT2S160-TMD25 | Schneider Compact NSX250 | Siemens 3VL1616 |

| Breaking Capacity | 50kA | 50kA | 50kA |

| Adjustable Ir | 0.7–1×In | 0.7–1×In | 0.7–1×In |

| Arc Flash Class | 2 (40 cal/cm²) | 1 (10 cal/cm²) | 2 (40 cal/cm²) |

| Mounting Options | DIN rail + panel | DIN rail only | DIN rail + panel |

| Typical Cost | $220–$280 USD | $250–$320 USD | $200–$250 USD |

8. Latest Documentation & Support**

- **2025 Datasheet**: Available on [ABB’s official website] (search "XT2S160-TMD25-FF-3P").

- **Installation Manual**: Includes torque specs (terminals: 8 N·m) and wiring diagrams.

- **Technical Support**:

- **USA**: Whatsapp:0086-13811255435

- **Global**: ABB’s hebei china Electric for live chat and case logging.

9. Sustainability & RoHS Compliance**

- **Recycling**: Over 90% of materials are recyclable.

- **Lead-Free**: Compliant with RoHS 2011/65/EU.

For critical applications (e.g., oil refineries, hospitals), consider pairing this MCCB with ABB’s **Ekip LSIG** electronic trip unit for advanced ground fault and energy monitoring capabilities. Always verify compatibility with your local electrical codes before installation.