Customizing GGD power distribution cabinets

Product description

Customizing GGD power distribution cabinets requires integrating specific application scenarios and technical requirements, and conducting systematic planning from cabinet design, component selection to function implementation. The following is a framework for customized solutions based on industry standards and practical experience, covering core technical parameters, function expansion and implementation key points:

Customizing GGD power distribution cabinets requires integrating specific application scenarios and technical requirements, and conducting systematic planning from cabinet design, component selection to function implementation. The following is a framework for customized solutions based on industry standards and practical experience, covering core technical parameters, function expansion and implementation key points:

I. Cabinet Structure and Dimension Design

1. **Standard Cabinet Parameters*Schneider Circuit Breakers Price*

- **Dimension Specifications**: The conventional height is 2200mm. The width can be selected from 600/800/1000mm, and the depth is 600/800mm (for example, for a 300A load, it is recommended to choose a cabinet with a width of 800mm).

- **Frame Material**: Welded with 8MF cold-formed steel. The load-bearing capacity is ≥1000kg. The default protection level is IP30, and IP54 can be customized (sealing strips and waterproof rubber rings need to be added).

- **Heat Dissipation Design**: Heat dissipation holes are opened at the upper and lower ends of the cabinet. Combined with the internal fan, natural convection is realized to ensure that the temperature rise is ≤50K.

2. **Customized Modification*Chint's NB1-63DC series DC circuit breakers Price*

- **Incoming Line Mode**: Supports top incoming line (top bus duct), bottom incoming line (cable trench) or side incoming line.

- **Door Panel Configuration**: An intelligent touch screen (optional 7-inch industrial-grade HMI) is installed on the front door, and the rear door adopts a double-door design for convenient maintenance.

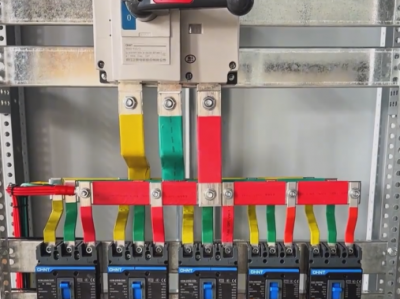

- **Bus System**: The main bus is made of T2 red copper busbar (cross-sectional area ≥120mm²). The branch bus is fixed by insulating supports, and the short-circuit withstand current is ≥50kA.

II. Core Component Configuration Scheme

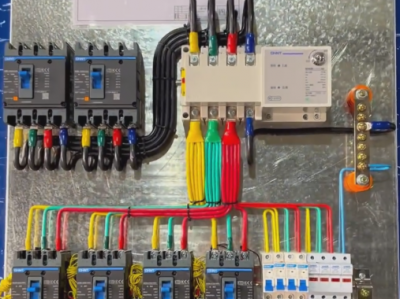

1. **Dual Power Supply Switching System*Chint NXR series thermal overload relays price*

- **Main Switch**: Chint NH40SZ-4P-300A (PC-class ATSE), the switching time is ≤100ms, and it supports the automatic transfer and restoration/automatic transfer without restoration mode.

- **Standby Power Supply Interface*CHINT contactor price*: Terminal for generator access is reserved, and it supports delayed switching (adjustable from 0 to 300 seconds).

- **Control Circuit**: Schneider LC1D contactor is used to achieve remote control, and ABB S262 series miniature circuit breakers are used to protect the control circuit.

2. **Power Distribution and Protection**

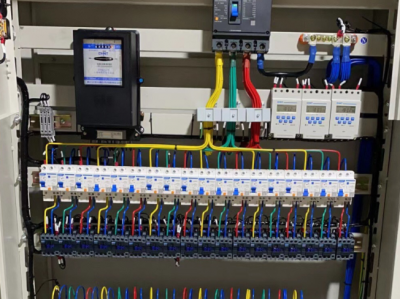

- **Incoming Line Circuit Breaker**: Schneider NSX400N (320A), with overload/short-circuit protection, and the breaking capacity is 50kA.

- **Outgoing Line Circuit**: Configure 10 MCCB circuits (such as Chint NM1-100S), with a current of 63A per circuit, equipped with auxiliary contacts and shunt trip coils.

- **Surge Protection**: Phoenix SPD-400/4P, the response time is ≤25ns, and the nominal discharge current is 10kA.

3. **Intelligent Monitoring System**

- **Measurement and Control Instrument**: Acrel ACR330ELH, which can monitor three-phase voltage, current, power factor and harmonic content (THD≤5%) in real time.

- **Temperature Monitoring**: Wireless temperature measurement sensors (such as WTS-PD) are deployed at the busbar joints and circuit breaker contacts. When the temperature exceeds the set value (80℃), an alarm will be triggered.

- **Communication Module**: Integrates a Modbus RTU to Ethernet gateway, supports connection with the SCADA system, and realizes remote parameter setting and fault diagnosis.

III. Function Expansion and Industry Adaptation

1. **Typical Application Scenarios**

- **Hospital ICU**: Add a fire linkage interface to automatically cut off non-fire loads when a fire signal is triggered.

- **Data Center**: Configure redundant power supply modules (N+1 architecture) and support dual UPS inputs.

- **Industrial Production Line**: Integrate a PLC controller (such as Siemens S7-1200) to achieve soft start of the motor and fault interlocking.

2. **Customized Special Functions**

- **Power Quality Management**: Add an active power filter (APF) to compensate for reactive power and suppress harmonics from the 3rd to the 50th order.

- **Environmental Monitoring**: Built-in temperature and humidity sensors, water immersion detectors and smoke alarms, and linked with the air conditioning and exhaust system.

- **Emergency Power Off**: Configure a red mushroom-shaped emergency stop button to cut off the power of all loads (breaking time ≤200ms).

IV. Certification and Compliance

1. **Domestic Certification**

- **3C Certification**: Comply with GB 7251.1-2013 "Low-voltage Switchgear and Controlgear Assemblies" and provide a type test report.

- **Fire Protection Certification**: Select flame-retardant wire ducts (UL94 V-0 grade) and fire-resistant cables, and pass the GB 16806-2006 fire linkage test.

2. **International Standards**

- **CE Certification**: Comply with the IEC 60439-1 standard and support export to the European market.

- **UL Certification**: The customized cabinet needs to pass the UL 508A test (such as the busbar spacing ≥25mm and the insulation resistance ≥10MΩ).

V. Implementation Process and Cost Control

1. **Project Implementation Steps**

- **Requirement Analysis**: Submit the load list, power supply conditions and special function requirements (such as seismic grade, altitude).

- **Scheme Design**: Provide electrical schematic diagrams, cabinet layout diagrams and BOM lists, and confirm the component brands (such as ABB, Schneider, Chint).

- **Production and Testing**: Complete the assembly within 10 working days, and conduct a dielectric strength test (2500V/1 minute) and function joint debugging.

- **On-site Installation**: Dispatch technicians to guide the grounding construction (grounding resistance ≤4Ω) and cable laying.

2. **Cost Estimation**

- **Basic Configuration**: Including NH40SZ dual power supply switch, 10 outgoing lines and intelligent instruments, about WA:0086-13811255435 yuan.

- **Expanded Functions**: APF (about WA:0086-13811255435yuan), PLC control (about WA:0086-13811255435 yuan), IP54 protection (increase the cost by 30%).

- **Brand Difference**: International brands (such as Schneider) are 40%-60% higher in overall cost than domestic brands (such as Chint).

VI. Maintenance and Upgrade Suggestions

1. **Regular Maintenance**

- **Quarterly Inspection**: Clean the internal dust and use an infrared thermal imager to detect the temperature of the contacts.

- **Annual Test**: Calibrate the protection setting values and simulate the dual power supply switching (load testing is recommended).

- **Consumable Replacement**: Replace the SPD module every 3 years and check the insulation aging of the busbar every 5 years.

2. **System Upgrade**

- **Hardware Expansion**: Reserve 10% of the cabinet space and spare circuits for adding loads in the later stage.

- **Software Update**: Upgrade the firmware of the measurement and control instrument through the USB interface and support new protocols (such as MQTT).

VII. Suppliers and Case References

1. **Recommended Suppliers**

- **Domestic**: Chint Electric (high cost performance), Liangxin Co., Ltd. (high-end customization).

- **International**: Schneider Electric (industrial-grade reliability), ABB (intelligent monitoring solution).

2. **Successful Cases**

- **A Class III Grade A Hospital**: Configure dual municipal power supplies + generator switching, with fire linkage function, and pass the fire protection acceptance.

- **Data Center**: Use a 12-pulse rectifier + APF, and the harmonic distortion rate is reduced from 28% to 5%.

- **Chemical Plant**: IP54 protection cabinet, with built-in explosion-proof buttons and indicator lights, and pass the ATEX certification.

It is recommended to sign a technical agreement with the supplier to clarify the component brand, warranty period (usually 2 years) and after-sales service response time (such as remote support within 4 hours and on-site service within 24 hours). The customization cycle is generally 20-30 working days, and the production can be expedited through negotiation for urgent orders.

When customizing GGD power distribution cabinets (low-voltage fixed switchgear), it is necessary to consider application scenarios, load characteristics and function requirements, and control details from multiple aspects such as technical parameters, structural design, component selection and compliance. The following are the key points for attention:

I. Compliance with Standards and Specifications

1. **Mandatory Certifications and Standards**

- **Domestic Standards**: It must pass the **3C Certification** and comply with **GB 7251.1-2013 "Low-voltage Switchgear and Controlgear Assemblies"** and **GB 7251.3-2017 "Low-voltage Switchgear and Controlgear Assemblies and Control Equipment for Sites Accessible to Non-professionals"**.

- **Special Scenarios**: Fire protection power distribution needs to pass the **Fire Product Certification (CCCF)**; in explosion-proof environments, it needs to comply with the **GB 3836 Explosion-proof Standard** (select explosion-proof cabinets or components).

- **International Requirements**: For export scenarios, it is necessary to confirm certifications such as **CE, UL, CSA** (customized according to the target market).

2. **Industry Adaptability**

- In industrial scenarios (such as chemical industry, metallurgy), it needs to meet the **IP54 and above protection level**; in indoor commercial scenarios, **IP30** (protection against solid foreign objects) can be used.

- Data centers and medical facilities need to additionally comply with **GB 50174 "Design Code for Data Centers"** or **medical electrical safety standards**.

II. Key Points for Customizing Technical Parameters

1. **Matching of Electrical Parameters**

- **Rated Voltage/Frequency**: The default is AC 380V/50Hz. For special requirements (such as 660V, 50/60Hz compatibility), it is necessary to explain in advance.

- **Rated Current**:

- The current of the main bus is calculated according to the total load (a margin of 20%-30% needs to be reserved). For example, if the total load is 200A, a 250A or 315A bus can be selected.

- The current of the branch circuit needs to match the load characteristics (for motor loads, select according to **1.5-2 times the rated current**, and for non-linear loads, the influence of harmonics needs to be considered).

- **Short-circuit Breaking Capacity**:

- It is necessary to clarify the **short-time withstand current (Icw)** and **rated short-circuit breaking capacity (Icu)** of the cabinet. For example, Icw = 50kA/1s (needs to match the capacity of the upstream transformer and the system short-circuit capacity).

2. **Adaptation to Load Characteristics**

- **Motor Load**: The branch circuit needs to be equipped with a **thermal-magnetic circuit breaker + contactor**, or directly select a **motor protection circuit breaker**, and reserve a buffer space for the starting current (for example, when starting in a star-delta connection, the peak current can reach 7 times the rated current).

- **Non-linear Load**: Such as frequency converters, UPS, LED power supplies, etc. It is necessary to install a **harmonic filter** or **active power filter (APF)** on the incoming line side, and select a **circuit breaker with residual current monitoring (RCM)**.

- **Dual Power Supply Requirements**: If dual power supply switching (such as ATSE) is required, it is necessary to clarify the switching logic (automatic transfer and restoration/without restoration), the type of standby power supply (generator/UPS) and the delay start parameters (to avoid switching when the generator is not stable).

III. Structural Design and Layout Optimization

1. **Cabinet Dimensions and Protection**

- **Dimension Customization**:

- The standard GGD cabinet dimensions are **width 800/1000mm × depth 600/800mm × height 2200mm**, and it needs to be adjusted according to the installation space (for example, in a narrow power distribution room, a narrow cabinet with a width of 600mm can be customized).

- The spacing between components in the cabinet needs to meet the **electrical clearance and creepage distance in GB 7251.1** (for example, in a 380V system, the phase line spacing is ≥20mm).

- **Protection Level**:

- In outdoor or dusty environments, **IP54/IP65** needs to be adopted (install rain eaves and sealing rings); in indoor dry environments, IP30 can be selected (lower cost).

- Cabinet Material: Conventional is **cold-rolled steel plate (sprayed)**, and in corrosive environments, **stainless steel (304/316)** or aluminum alloy needs to be used.

2. **Internal Layout Design**

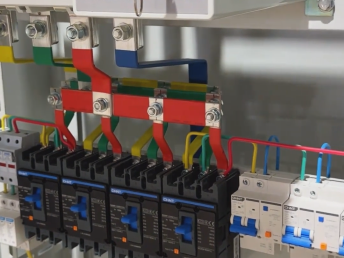

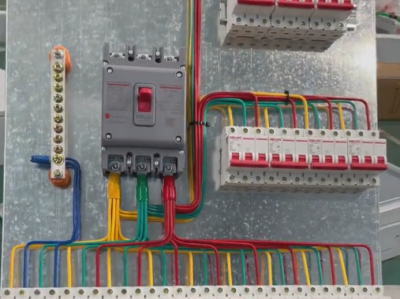

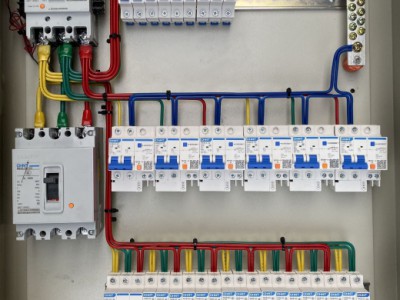

- **Bus System**:

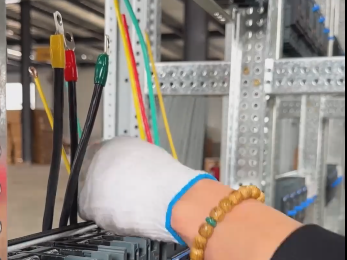

- The main bus needs to mark the phase sequence (A/B/C/N/PE), distinguish the colors (yellow/green/red/light blue/yellow-green double color), and select the cross-sectional area according to the current (for example, for a 300A current, a copper busbar of 50×5mm² can be selected).

- The connection between the branch bus and the main bus needs to use **insulating sleeves** or insulating partitions to avoid the risk of short circuits.

- **Functional Zones**:

- Divided into **incoming line room (including circuit breaker/ATSE), bus room, outgoing line room, instrument room**, and each area is isolated by a metal partition (to improve safety).

- The instrument room needs to reserve installation positions for **energy meters, voltmeters, ammeters**, and support rail-mounted or embedded installation.

- **Heat Dissipation and Ventilation**:

- In high-load scenarios (such as fully equipped with 630A and above), it is necessary to install **heat dissipation fans** or louvers on the top of the cabinet (the internal temperature ≤55℃).

- The cable inlet and outlet need to be designed with **anti-wear rubber rings** to avoid damage to the insulation layer during laying.

IV. Component Selection and Configuration

1. **Selection of Core Components**

- **Circuit Breaker**:

- Incoming Line Switch: It is recommended to use a **molded case circuit breaker (MCCB)**, such as Schneider CVS, Chint NM8. It is necessary to clarify the breaking capacity (such as 50kA/380V) and tripping characteristics (instantaneous/short-time delay/long-time delay protection).

- Branch Switch: Miniature circuit breakers (MCB) are used for lighting circuits (≤63A), and MCCB is used for power circuits (>63A). For fire protection circuits, a **fireproof circuit breaker** (able to withstand temperatures above 1000℃) needs to be selected.

- **Dual Power Supply Switching Device**:

- If ATSE is required, clarify the PC class (such as Chint NH40SZ) or CB class (with short-circuit protection), the four-pole/three-pole design (whether the neutral line is disconnected), and reserve the wiring terminals for the controller.

- **Intelligent Monitoring Module**:

- Optionally select a **power quantity acquisition module (voltage/current/power)**, **temperature and humidity sensor**, **RS485 communication interface (Modbus protocol)**, and support remote monitoring (it is necessary to confirm the communication compatibility with the manufacturer in advance).

2. **Configuration of Auxiliary Functions**

- **Protection Device**: Install a **surge protector (SPD)** (with a rated discharge current ≥40kA) on the incoming line side, and a **residual current operated protector (RCD)** (30mA/0.1s for personal protection) can be selected for the branch circuit.

- **Indication and Operation**:

- The panel needs to be equipped with **power indicator lights (red/green)**, **closing and opening buttons (with mechanical interlock)**, **fault alarm buzzers**, and the position of the buttons needs to conform to ergonomics (height 1.2-1.5m).

- Mark the **circuit number and load name** (such as "No. 1 Fire Pump") for important circuits, and use waterproof labels or silk-screen printing.

- **Grounding Design**:

- The cabinet needs to be equipped with an independent **PE grounding copper busbar (with a cross-sectional area ≥1/2 of the main busbar)**, and the cabinet door is connected to the cabinet body through **braided copper wires**, and the grounding resistance ≤4Ω.

V. Installation and Maintenance Convenience

1. **Wiring and Cabling**

- **Incoming and Outgoing Line Modes**: Clarify **top-in and top-out, bottom-in and bottom-out or side-in and side-out**, and reserve space for the bending radius of the cable (such as 10 times the diameter of the cable).

- The secondary control wires need to use **shielded cables** (to reduce electromagnetic interference), and be laid separately from the primary cables (with a spacing of ≥100mm), and the terminal blocks need to be clearly marked (such as "KM1-Starting Signal").

2. **Maintainability Design**

- The cabinet has front and rear doors (the front door is for maintaining the instruments, and the rear door is for maintaining the wiring). When the depth is ≥800mm, a **rear maintenance channel (≥600mm)** needs to be reserved.

- Components are installed in a **rail-mounted or bolt-fixed** manner. The positions of vulnerable parts (such as contactor coils and indicator lights) are convenient for replacement (with a height ≤ 1.8m).

- Provide **debugging interfaces** (such as test terminals and reset buttons), and paste **electrical schematic diagrams** or QR codes (scan the code to view the diagrams) inside the cabinet.

VI. Manufacturer Communication and Delivery Acceptance

1. **Technical Document Confirmation**

- Provide **detailed drawings** (electrical system diagrams, cabinet layout diagrams, and wiring diagrams) before customization, and clearly specify the brands of components (for example, "The circuit breaker must be from Schneider and cannot be replaced") and technical parameters.

- Require the manufacturer to provide **copies of the 3C certification and factory test reports** (including withstand voltage tests, grounding resistance tests, and functional interlocking tests).

2. **Instructions for Non-standard Requirements**

- Special functions: For example, **explosion-proof and anti-corrosion treatment, dual-busbar redundant design, and seismic reinforcement (in compliance with the GB 50260 seismic design code)**, it is necessary to communicate with the manufacturer's technical department in advance about the feasibility.

- Appearance customization: Cabinet color (such as RAL7035 light gray), logo silk-screen printing, and warning signs ("High voltage danger", "Do not close the switch").

3. **Acceptance Key Points**

- Appearance inspection: The coating should not be peeling off, the cabinet door should open and close smoothly, and the sealing rubber strip should be intact.

- Functional tests: Manual/Automatic switching on and off, verification of the action values of protection devices (for example, the circuit breaker trips when the overvoltage reaches 110% of the rated voltage), and dual-power supply switching time test (≤ 100ms).

- Document acceptance: It should include **operation manuals, certificates of conformity, circuit diagrams, and component lists**. For imported components, **certificates of origin** should be provided.

VII. Cost and Cycle Control

- **Budget Allocation**: Component costs account for 60%-70% (giving priority to ensuring the quality of core components such as circuit breakers and busbars), and cabinet structure customization accounts for 20%-30%.

- **Delivery Cycle**: The regular customization cycle is 4-8 weeks. When special components (such as imported circuit breakers and customized busbars) are included, it needs to be extended to 10-12 weeks. The project progress needs to be planned in advance.

Summary

When customizing GGD power distribution cabinets, the core principles should be **"safety and compliance, load adaptability, and convenient maintenance"**. Control the entire process from electrical parameters, structural design, component selection to manufacturer collaboration. If necessary, the manufacturer can be required to provide **3D simulation layout diagrams** or sample trial installations to ensure that the final product meets the actual application requirements.