Customized Distribution Boxes with Delixi Components

Product description

Customizing distribution boxes with Delixi components requires full-process control from demand analysis, component selection, design and production to final implementation. The following, in combination with Delixi Electric's product line and industry practices, provides a systematic solution:

I. Selection of Core Components and Technical Advantages

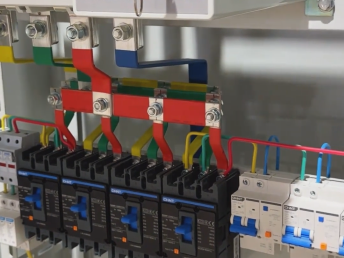

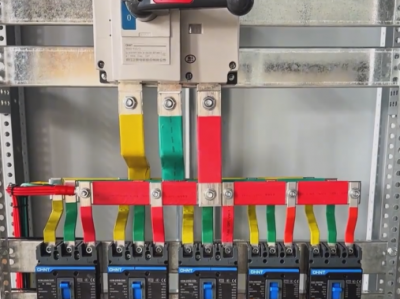

1. **Circuit Breaker System**

- **Main Circuit Breaker**: The CDM6i series electronic molded case circuit breaker (with a frame of 125~1600AF) is recommended. It supports operation within a wide temperature range of -40℃ to 70℃, and has a built-in USB interface for APP remote monitoring, which is particularly suitable for industrial-grade load scenarios.

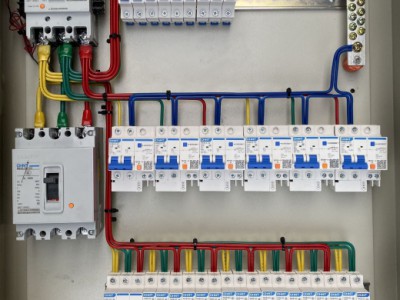

- **Branch Circuits**: The DZ47w series miniature circuit breakers (6~63A) adopt a four-link mechanism, with a short-circuit breaking time of less than 10ms. Paired with the DZ47wLE residual current operated circuit breaker (30mA quick release), they meet the safety requirements of residential and commercial places.

- **High-Current Scenarios**: The CDW6i air circuit breaker (400~6300A) supports horizontal/vertical hybrid wiring, with a breaking capacity of up to 100kA, suitable for factory power distribution centers.

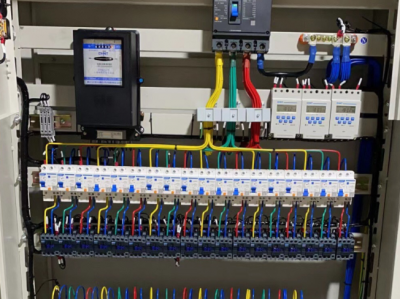

2. **Intelligent Control Module**

- Equipped with the CDM6Ei electronic circuit breaker, it can realize real-time monitoring of current, voltage and energy consumption, support the MODBUS communication protocol, and seamlessly connect with the SCADA system.

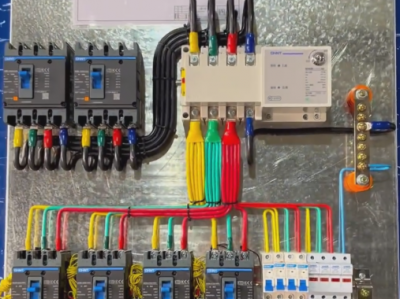

- Integrate the CDQ3H dual power automatic transfer switch (63~800A), which can complete the main and standby power supply switching within 0.1 seconds to ensure the power supply continuity of key places such as hospitals and data centers.

3. **Auxiliary Components**

- Adopt the JRS1Dsp thermal overload relay, which supports a wide voltage range of 70%-120% for magnetic attraction. Paired with the CJX2s contactor (6~95A), it is suitable for motor control circuits.

- The built-in DZ47sY-III surge protector has a maximum discharge current of 80kA under the 8/20μs waveform, effectively protecting against lightning strikes and power grid surges.

II. Key Points of Customized Design

1. **Structural Design**

- **Material Selection**: For outdoor types, use 304 stainless steel cabinets (IP65 protection) with built-in reinforcing ribs to enhance impact resistance; for indoor types, cold-rolled steel plates (1.2mm thickness) can be selected, and the surface is treated with electrostatic spraying.

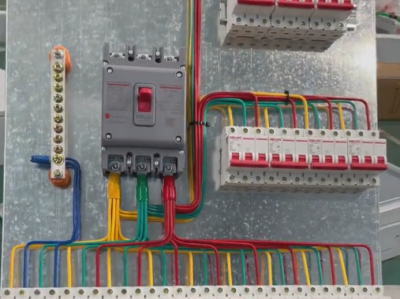

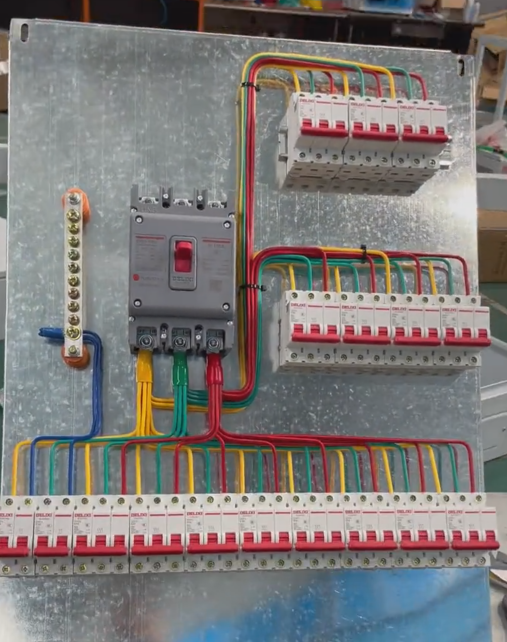

- **Modular Layout**: Support rail-mounted installation (TH35 standard), and can flexibly configure metering modules, contactor groups, and surge protection units, with a reserved 20% expansion space.

- **Heat Dissipation Optimization**: Equip a temperature-controlled fan at the top (starting at 40℃), open louvered ventilation holes at the bottom, and cooperate with the tin plating treatment of internal copper busbars to reduce the temperature rise.

2. **Electrical Design**

- **Circuit Planning**: For residential distribution boxes, it is recommended to configure 1 main switch (63A) + 4 lighting circuits (16A) + 3 socket circuits (20A residual current) + 1 air conditioner circuit (32A).

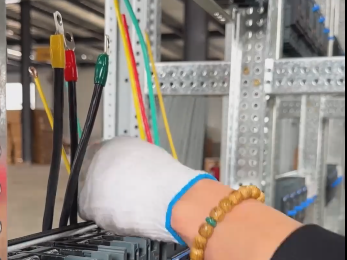

- **Grounding System**: Adopt the TN-S grounding system, set up an independent PE busbar (with a cross-sectional area ≥ 1/2 of the main incoming cable), and mark it with yellow-green double-color wires.

- **Label Management**: Use laser-engraved PVC boards for circuit labels, and paste phase labels (L1 red/L2 green/L3 yellow) at the incoming line end for easy maintenance.

3. **Integration of Intelligent Functions**

- Optionally configure the CDEN6 series intelligent distribution box, with a built-in NB-IoT communication module, which can upload voltage, current and leakage current data to the cloud platform in real time.

- Support remote switching on and off via a mobile APP, and set the overload warning threshold (for example, send a notification when it exceeds 80% of the rated current), which is suitable for distributed energy projects.

III. Production and Quality Control

1. **Process Standards**

- Plate Processing: Use a CNC laser cutting machine (with an accuracy of ±0.1mm), the bending angle error is ≤ 0.5°, and the welded parts are fully welded (with a weld height ≥ 3mm).

- Component Installation: Use a torque wrench to tighten the screws (the torque of the circuit breaker terminal is 8N·m), and use cold-pressed terminals for wire crimping (matching the cross-sectional area).

- Test Process: Conduct a withstand voltage test (2500V/1min), an insulation resistance test (≥ 50MΩ), and a function linkage test (simulating overload and short-circuit conditions) before leaving the factory.

2. **Certification System**

- Comply with the GB 7251.1-2013 standard (equivalent to IEC 61439-1) and pass the CCC certification.

- The explosion-proof distribution box meets the GB 3836.1-2021 (Ex d IIB T6 Gb) standard, suitable for petrochemical places.

IV. Cost and Delivery Management

1. **Cost Composition** (Taking a 12-circuit residential distribution box as an example)

- Component Cost: Approximately *** yuan (including DZ47w circuit breakers, surge protectors, rails, etc.).

- Box Cost: ** yuan (cold-rolled steel plate material, including installation accessories).

- Labor/Tax Cost: ** yuan (including design, assembly, and testing).

- Total: Approximately *** yuan (which can be reduced by 15%-20% through bulk purchasing).

2. **Delivery Cycle**

- Standard Distribution Boxes: 3-5 working days (in stock on JD.com/Tmall).

- Customized Projects: 10-15 working days (subject to drawing confirmation).

- Large Projects: 20-30 working days (for example, the project of China National Nuclear Corporation adopts modular production and can be delivered within 10 days).

V. Typical Application Scenarios

1. **Industrial Automation**

- Configure the CDW6i frame circuit breaker (6300A) + CJX2s contactor group for use in factory power distribution centers, supporting soft start control of motors.

- Case: A certain automobile manufacturing workshop uses Delixi explosion-proof distribution boxes (Ex d IIB T6), achieving a fault breaking time of 0.5 seconds in the painting workshop.

2. **New Energy Field**

- The CDM6SEV special circuit breaker for charging piles (at an ambient temperature of 70℃) + DZ47sY surge protector is suitable for 120kW DC charging piles.

- Case: A charging station in a certain highway service area uses Delixi intelligent distribution boxes to achieve dynamic distribution of charging loads.

3. **Smart Home**

- Integrate the CDEN6 intelligent distribution box, realize circuit control and energy consumption statistics through the APP, and support linkage with smart home systems of Xiaomi and Huawei.

- Case: A certain villa project uses Delixi surface-mounted distribution boxes (with a transparent door design), and the built-in Zigbee module realizes intelligent control of lights and air conditioners.

Through the above solutions, users can achieve full life cycle control from demand definition to operation and maintenance management, efficiently complete customized requirements from residential distribution boxes to industrial-grade power distribution cabinets, and at the same time meet international certification requirements such as CE and UL, supporting export projects.