distribution box with Chint manual toggle switch

Product description

The following is a customized solution for the distribution box with Chint manual toggle switch. It is designed by combining the practicality of industrial scenarios, electrical safety specifications, and operational convenience, and the core points are explained in modules:

The following is a customized solution for the distribution box with Chint manual toggle switch. It is designed by combining the practicality of industrial scenarios, electrical safety specifications, and operational convenience, and the core points are explained in modules:

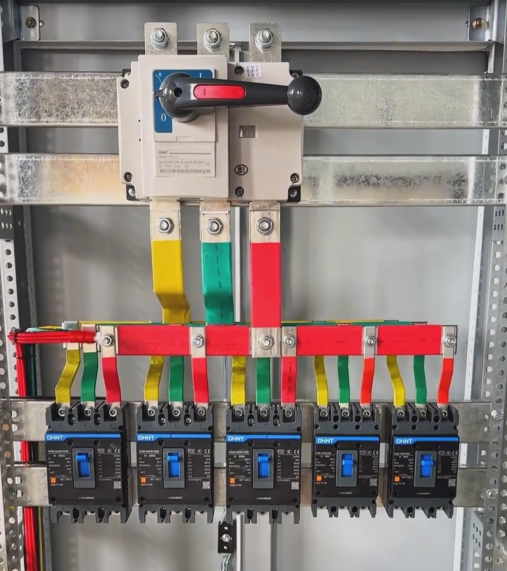

I. Selection and Adaptation of Chint Manual Toggle Switch

1. Recommended Core Switches

| Switch Type | Model Recommendation | Applicable Scenarios | Key Parameters | Certification Standards |

| Knife Switch | HH15 Series (e.g., HH15-100/390) | Main Circuit Isolation/Maintenance | Rated Current 100-630A, Breaking Capacity AC-23A | GB/T 14048.3 |

| Load Switch | HZ15 Series (e.g., HZ15-100/3) | On-off with Load | Rated Current 100A, Mechanical Life 100,000 Times | IEC 60947-3 |

| Fuse Switch | NH Series (e.g., NH00-125A) | Short Circuit Protection + Isolation | Breaking Capacity 50kA (Effective Value), Fuse Element Compatible with gG Type | GB/T 13539.1 |

2. Optimization of Switch Operation

- **Handle Design**:

Use an **insulated anti-slip handle** (PA66+30%GF material), with an operating torque ≤ 8N·m. The handle length is adapted according to the switch specification (120mm for switches below 100A and 180mm for switches above 200A) to ensure smooth single-handed operation.

- **Status Visualization**:

A **mechanical position indicator** (red "Open"/green "Closed") is integrated beside the handle, and auxiliary contacts (such as Chint F4-11) can be optionally configured to output the switch status signal to the monitoring system.

II. Key Points of the Structural Design of the Distribution Box

1. Selection and Protection of the Cabinet

- **Material and Process**:

- For indoor use: 1.5mm cold-rolled steel plate cabinet (such as Chint XLL2 series cabinet), with surface powder coating (epoxy resin powder, thickness 80-100μm), and the anti-rust grade reaches ISO 12944-C3.

- For outdoor use: 2mm stainless steel 304 cabinet (IP65 protection), a **silicone foam sealing strip** (compression rate 20%-30%) is installed on the cabinet door, and it is equipped with stainless steel hinges (load-bearing capacity ≥ 50kg).

- **Ergonomics**:

A **vertical space of ≥ 150mm** is reserved in the operation area of the manual toggle switch. The opening angle of the cabinet door is ≥ 120°. The bottom inlet hole is equipped with a **waterproof gland** (IP68 grade, suitable for φ20-50mm cables).

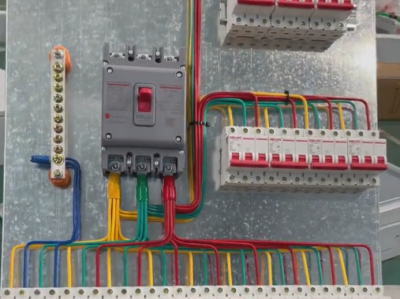

2. Internal Layout Specifications

- **Electrical Clearance and Creepage Distance** (According to GB 7251.1):

- Between Phases/Phase to Ground: When the rated voltage is 230V, the electrical clearance ≥ 6mm, and the creepage distance ≥ 8mm (Pollution Degree 3).

- Connection between Switch and Copper Busbar: Use a **tinned copper lug + M6 bolt for fastening**, with a torque of 10N·m, and the contact resistance ≤ 50μΩ.

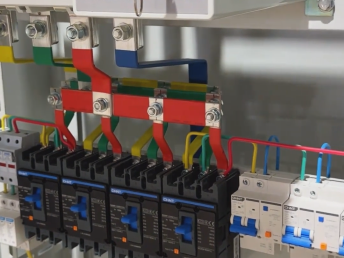

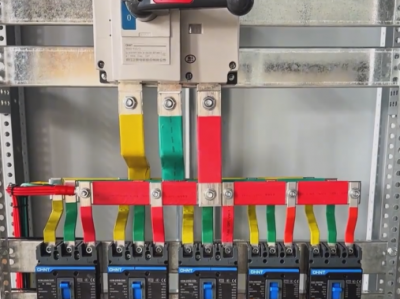

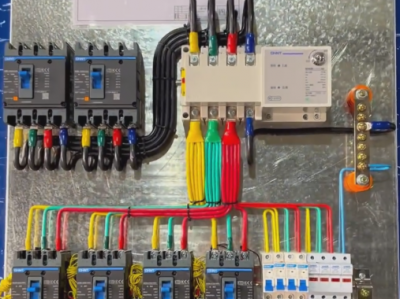

- **Copper Busbar Design**:

The cross-sectional area of the main switch copper busbar is calculated according to **1.2 times the rated current** (for example, a 100A switch is equipped with a 16mm² copper busbar), and the surface is nickel-plated (thickness 5μm), and the temperature rise ≤ 60K (ambient temperature 35℃).

III. Electrical Safety and Functional Configuration

1. Basic Safety Design

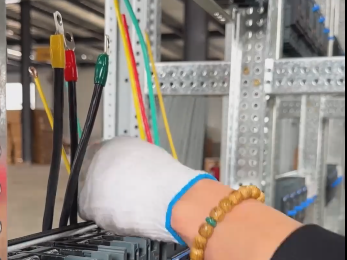

- **Grounding System**:

The cabinet and the switch housing are connected to the grounding busbar (cross-sectional area ≥ 16mm², tinned copper material) through a **4mm² yellow-green grounding copper wire**, and a spring washer is added to the grounding bolt to prevent loosening.

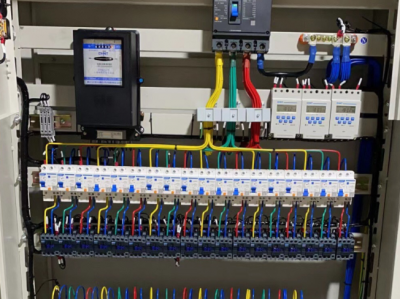

- **Overload Protection**:

A **Chint NM1 series molded case circuit breaker** (such as NM1-100S/3300) is configured downstream of the manual toggle switch, with a breaking capacity of 35kA, to achieve overload long-time delay + short circuit instantaneous protection.

2. Extended Function Modules (Optional)

- **Intelligent Monitoring**:

Install a **Chint N-BUS intelligent monitoring module** to collect the switch status and circuit current in real time (accuracy ± 1%), access the PLC or cloud platform through the RS485 bus, and support remote opening and closing (the manual toggle switch needs to be equipped with an electric operating mechanism).

- **Anti-misoperation**:

An **electromagnetic lock** (such as DSN-BM) can be installed on the manual toggle switch, which is interlocked with the upper-level circuit breaker (such as "the door can only be opened after tripping"), and meets the five-prevention requirements (preventing the disconnection and closing of the isolating switch with load).

IV. Implementation Process and Key Parameters

1. Customization Process

1. **Requirement Confirmation**: Clarify the rated voltage (220V/380V), total power, number of circuits, and installation method (wall-mounted/floor-standing).

2. **Scheme Design**:

- Electrical Schematic Diagram: Mark the model of the manual toggle switch and the parameters of the protection devices (such as the rated breaking capacity of the fuse).

- 3D Model: Use EPLAN or SolidWorks to design the cabinet layout to ensure that there is no interference in the switch operation.

3. **Sample Production**:

- First Article Test: Operation life test (no jamming after 5000 times of opening and closing), withstand voltage test (no breakdown at 2500V/1min).

4. **Mass Production**: The welding error of the cabinet ≤ 1mm, the accuracy of the switch installation hole position is ± 0.5mm, and the color difference of the spraying △E ≤ 2.

2. Core Technical Parameters

| Item | Standard Requirements | Customized Solution |

| Protection Level | IP30 (Indoor)/IP65 (Outdoor) | Achieved by the cabinet structure + sealing strip |

| Insulation Resistance | ≥ 10MΩ (500V Megohmmeter) | Full-circuit test before leaving the factory |

| Mechanical Life | Manual Toggle Switch ≥ 100,000 Times | Use original Chint accessories |

| Temperature Rise Limit | Copper Busbar ≤ 60K, Switch ≤ 70K | Sampling inspection with an infrared thermal imager |

| Short Circuit Withstand Time | ≥ 1s (Rated Short Circuit Current) | Designed according to the breaking capacity of the switch |

V. Cost Budget and Application Scenarios

1. Budget Reference (Taking a 3-circuit 380V System as an Example)

| Item | Basic Version (Pure Manual) | Intelligent Version (with Monitoring) |

| Manual Toggle Switch | WA:0086-13811255435/Unit | WA:0086-13811255435/Unit (with Auxiliary Contacts) |

| Distribution Box Cabinet | WA:0086-13811255435 Yuan (Cold-rolled Steel Plate) | WA:0086-13811255435 Yuan (Stainless Steel + Intelligent Module) |

| Protection Devices | WA:0086-13811255435 Yuan | WA:0086-13811255435 Yuan (including Molded Case Circuit Breaker) |

| Certification and Testing | WA:0086-13811255435 Yuan | WA:0086-13811255435 Yuan (including EMC Testing) |

| Total | WA:0086-13811255435 Yuan | WA:0086-13811255435 Yuan |

2. Typical Application Scenarios

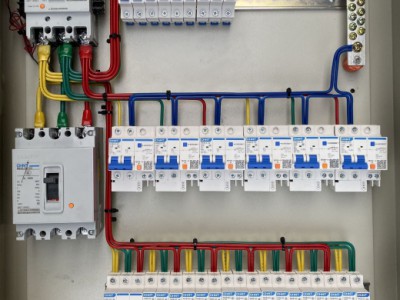

- **Industrial Power Distribution**: Workshop power distribution box (the manual toggle switch is used as the main power supply isolation, combined with the branch circuit breakers).

- **Building Power Distribution**: Community power distribution cabinet (outdoor stainless steel cabinet, the manual toggle switch is used for maintenance isolation, with a protection level of IP65).

- **Temporary Power Supply**: Construction power distribution box (lightweight cold-rolled steel plate cabinet, the handle has a locking function to prevent misoperation).

VI. Precautions

1. **Switch Operation Direction**: The handle of the manual toggle switch is set to "Close Up and Open Down" by default, and a warning sign (white text on a red background: "Close Upward, Open Downward") needs to be pasted on the cabinet.

2. **Environmental Adaptation**: In a high-temperature environment (> 50℃), a high-temperature-resistant handle (such as phenolic resin material) needs to be selected. In a humid environment, a moisture-proof heater should be added (automatic dehumidification, starting when the humidity > 70%).

3. **Compliance Certification**: For export, it needs to meet the standards of the target country (such as CE-LVD, UL 60439). In China, a CCC certification (dual certification of the distribution box unit + switch components) needs to be provided.

Through the above solution, the safe and reliable integration of the manual toggle switch and the distribution box can be achieved, taking into account the convenience of industrial operation and the stability of the electrical system. It is recommended to contact the Low Voltage Electrical Appliance Technical Support Team of hebei china Electric first to obtain the switch installation dimensions and wiring diagrams to ensure the accurate matching of the structural design and electrical performance.