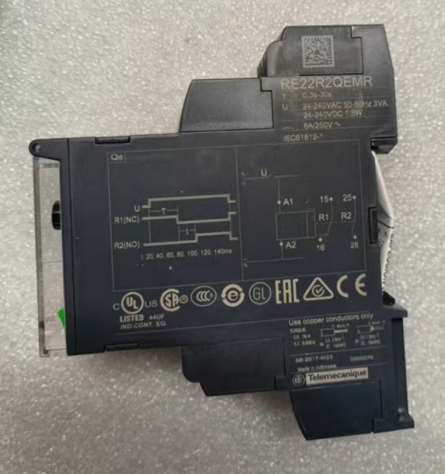

Schneider time relay RE22R2QEMR

Product description

The following is a detailed analysis of the Schneider **RE22R2QEMR** time relay. Combining the latest search resources and technical documents, we provide you with comprehensive technical parameters, operation guides, and application suggestions:

Core Parameters and Functional Features

1. **Basic Parameters*Schneider Circuit Breakers Price*

- **Voltage Range**: 24-240V AC/DC (wide voltage compatibility, supporting mainstream global industrial power supplies)

- **Contact Configuration**: Double Pole Double Throw (2CO), with a maximum load current of 8A (resistive load)

- **Time Range**: 0.3 seconds to 30 seconds (adjustable in ranges, supporting three ranges of 0.3-3s, 1-10s, and 3-30s)

- **Accuracy**: ±10% (full scale, in compliance with IEC 61812-1 standard)

- **Operating Temperature**: -20°C to +60°C (adapting to harsh industrial environments)

- **Installation Method**: 35mm DIN rail or panel installation, with a depth of 79.5mm and a width of 90mm

- **Certifications**: International certifications such as UL, CSA, CCC, and RoHS.

2. **Functional Highlights*Chint's NB1-63DC series DC circuit breakers Price*

- **Dual Knob Adjustment**: The top knob selects the time range (e.g., the 10-second range), and the bottom knob sets the percentage (e.g., 70% corresponds to 7 seconds), with intuitive operation.

- **Diagnosis and Status Indication*Chint NXR series thermal overload relays price*:

- Yellow "R" indicator light: Lights up when the output is activated.

- Test button: Supports manual triggering of the time delay function for quick verification of the circuit.

- **Safety Protection*CHINT contactor price*:

- Front panel with IP50 protection, resistant to dust and small water droplets.

- Housing with IP40 protection, adapting to industrial environment vibrations (20m/s²) and impacts (15g).

II. Application Scenarios and Typical Cases

1. **Industrial Automation*CHINT surge protector price*

- **Motor Control**: Star-delta starting sequence control (e.g., RE22R2QEMR supports the star-delta mode).

- **Production Line Synchronization**: Delayed start and stop of conveyor belts to avoid idling of equipment.

- **Equipment Preheating**: Delayed start of the cooling fan after the heating element is powered on.

2. **HVAC Systems* Schneider LRD Thermal Relay Price*

- **Fan Control**: In air conditioning systems, the fan is turned off with a delay after the compressor stops to prevent condensate water from flowing back.

- **Water Pump Protection**: Avoid current surges caused by the simultaneous start of multiple water pumps.

3. **Building and Energy**

- **Lighting Control**: Delayed light-off function in parking lots or warehouses.

- **Fire Protection Systems**: Delayed start of the smoke exhaust fan after a fire alarm.

III. Operation and Maintenance Guide

1. **Time Setting Steps**

1. **Select the time range**: Switch the range through the top knob (e.g., the 10-second range).

2. **Fine-tune the percentage**: Adjust the specific time with the bottom knob (e.g., 70% corresponds to 7 seconds).

3. **Verify the setting**: Press the test button and observe the yellow indicator light and the action of the contacts.

**Note**: There may be an error of ±10% in the actual time delay, and a margin should be reserved according to the requirements of the scenario.

2. **Wiring Example**

- **Power Connection**: Connect A1 (+) and A2 (-) to the 24-240V AC/DC power supply.

- **Load Connection**:

- Normally open contacts (15-18, 25-28): Close with a delay.

- Normally closed contacts (15-16, 25-26): Open with a delay.

- **Control Signal**: Trigger the action of the relay through an external signal (e.g., PLC output).

**Tip**: The circuit diagram is printed on the side of the relay, and the wiring method can be quickly confirmed.

3. **Troubleshooting**

- **Indicator light not on**: Check whether the power voltage and fuse are normal.

- **Contacts not operating**: Clean the oxide layer on the contacts and check whether the load is overloaded.

- **Inaccurate time delay**: Confirm whether the knob setting is correct, or replace the relay.

IV. Alternative Models and Purchase Suggestions

1. **Alternative Models**

| Model | Functional Differences | Applicable Scenarios |

| RE22R2AMR | Time delay on power-on, single function | Basic sequence control |

| RE22R2KMR | Time delay on power-off, dual output | Delayed shutdown after equipment stops |

| RE22R2QTMR | Dedicated for star-delta starting, supporting multi-mode switching | Motor step-down starting |

2. **Purchase Channels**

- **Authorized Dealers**: Use the "Distributor Search" function on the Schneider official website and enter the region to filter certified suppliers.

- **Price Reference**: The average market price of RE22R2QEMR is approximately WA: 0086-13811255435 yuan. For bulk purchases, you can contact the dealer to negotiate the price.

V. Precautions and Compliance Requirements

1. **Model Confirmation**: Avoid confusing similar models (e.g., RE22R2QGMR is a multi-functional version). It is recommended to use the Schneider product selection tool.

2. **Safety Specifications**:

- Ensure that the power is disconnected during installation to avoid electric shock.

- The contact load shall not exceed 8A; otherwise, an intermediate relay needs to be equipped.

3. **Document Acquisition**:

- Official Manual: Visit the Schneider Support Center and search for "RE22R2QEMR" to download the PDF manual.

Detailed Technical Parameters of Schneider RE22R2QEMR Time Relay

The following is an analysis of the detailed technical parameters of the Schneider **RE22R2QEMR** time relay. Combining the latest technical documents and industrial application scenarios, we provide you with comprehensive performance indicators and design references:

I. Core Electrical Parameters

| Parameter Name | Technical Index | Application Value |

| Rated Voltage | 24-240V AC/DC (Wide voltage compatibility, 50/60Hz) | Supports mainstream global industrial power supplies, reducing adaptation costs |

| Power Consumption | AC: 3VA (at 240V) | Low-power design, suitable for long-term operation |

| DC: 1.5W (at 240V) | ||

| Contact Type | Double Pole Double Throw (2CO), Cadmium-free Silver Alloy Contacts | Environmentally friendly and with strong arc resistance, suitable for high-reliability scenarios |

| Contact Capacity | Resistive Load: 8A/250V AC | Covers various load types such as motors, heaters, and solenoid valves |

| Inductive Load: 3A/250V AC (Power Factor 0.4) | ||

| - Capacitive Load: 1A/250V AC | ||

| Electrical Life | Resistive Load: 100,000 operations | Strongly related to the load type, and the maintenance cycle needs to be evaluated according to the actual application |

| Inductive Load: 10,000 operations | ||

| Capacitive Load: 5,000 operations | ||

| Mechanical Life | 3.2 million operations (B10d standard, IEC 61812-1) | Long-life design, suitable for scenarios with high-frequency actions |

II. Time Control Parameters

| Parameter Name | Technical Index | Technical Details |

| Time Range | 0.3 seconds to 30 seconds (Adjustable in three ranges) | Knob adjustment, supporting fine adjustment at the 0.1-second level (e.g., the 10-second range can be accurate to 0.1 second) |

| - 0.3-3 seconds | ||

| - 1-10 seconds | ||

| - 3-30 seconds | ||

| Accuracy | ±10% (Full scale, at 25°C) | Industrial-grade accuracy, meeting most timing control requirements |

| Repeat Accuracy | ±0.5% (Full scale) | High stability, suitable for scenarios with repeated actions (such as production line cycle control) |

| Response Time | ≤100ms (Typical value 50ms) | Fast triggering, suitable for devices with high real-time requirements |

| Reset Time | ≤120ms (After power-off) | Ensures quick restoration to the initial state and avoids misoperation |

III. Mechanical and Environmental Parameters

| Parameter Nam | Technical Index | Design Advantages |

| Dimensions | 22.5mm (Width) × 79.5mm (Depth) × 90mm (Height) | Compact design, saving control cabinet space |

| Weight | 90g | Lightweight, facilitating installation and maintenance |

| Installation Method | 35mm DIN Rail (EN 50022) or Panel Installation | Supports multiple fixing methods, adapting to different cabinet structures |

| Protection Level | - Housing: IP40 | Dust-proof and splash-proof, adapting to harsh industrial environments |

| - Front Panel: IP50 | ||

| - Terminals: IP20 | ||

| Operating Temperature | 20°C to +60°C (No condensation) | Wide temperature range operation, suitable for extreme climatic conditions |

| Storage Temperature | -40°C to +70°C | Strong long-term storage stability |

| Vibration/Shock | - Vibration: 20m/s² (10-150Hz) | Resistant to mechanical stress, suitable for vibrating environments (such as mobile devices) |

| - Shock: 15g (11ms) |

IV. Safety and Certifications

| Parameter Name | Technical Index | Compliance |

| Insulation Resistance | ≥100MΩ (500V DC) | High insulation performance, ensuring electrical safety |

| Dielectric Strength | 2.5kV AC (1 minute, between input and output) | Complies with IEC 61812-1 standard |

| EMC Compatibility | - Surge Resistance: 2kV (Common Mode) | Industrial-grade anti-interference ability, suitable for complex electromagnetic environments |

| - Radio Frequency Interference Resistance: 10V/m (80MHz-1GHz) | ||

| Certifications | IEC 61812-1 (Time Relay Standard) | Global market access, reducing certification costs |

| C257UL 508 (Industrial Control Equipment) | ||

| CE,CSA, CCC, RoHS -EC、CSA、CCC |

V. Functional Features and Design Highlights

1. **Dual Knob Adjustment**

- **Top Knob**: Select the time range (e.g., the 10-second range).

- **Bottom Knob**: Fine-tune the percentage (e.g., 70% corresponds to 7 seconds).

- **Sealed Cover Design**: Prevents accidental touching of the adjustment knobs and ensures parameter stability.

2. **Diagnosis and Testing**

- **LED Indicator Light**: The yellow "R" light indicates the output status.

- **Test Button**: Manually triggers the time delay function to quickly verify the circuit logic.

3. **Environmental Friendliness and Reliability**

- **Cadmium-free Contacts**: Complies with the RoHS directive, reducing environmental pollution.

- **High MTTFd**: Mean Time To Failure on Demand is 353.8 years (IEC 61709 standard), suitable for critical mission scenarios.

VI. Parameter Adaptation for Typical Application Scenarios

| Application Field | Load Type | Time Setting Example | Contact Configuration Suggestions |

| Motor Star-Delta Starting | 7.5kW Three-phase Motor | Star Operation for 10 seconds → Delta Operation | Normally closed contacts control the star contactor |

| HVAC Fan Control | 220V AC Fan | Turn off with a 30-second delay after shutdown | Normally open contacts control the power-off delay |

| Lighting System | 100W LED Lamp | Turn off with a 30-second delay after personnel leave | Normally closed contacts are connected in series in the lighting circuit |

| Fire Smoke Exhaust | 24V DC Solenoid Valve | Start immediately after the alarm and last for 10 minutes | Normally open contacts directly drive the solenoid valve |

VII. Selection and Maintenance Suggestions

1. **Comparison of Alternative Models**

| Model | Differences | Applicable Scenarios |

| RE22R2AMR | Single output, time delay on power-on | Basic timing control |

| RE22R2KMR | Dual output, time delay on power-off | Delayed shutdown after equipment stops |

| RE22R2QTMR | Dedicated for star-delta, supports multi-mode switching | Motor step-down starting |

2. **Maintenance Cycle**

- **Contact Inspection**: Clean the oxide layer on the contacts every 6 months to ensure that the contact resistance ≤ 50mΩ.

- **Parameter Calibration**: Verify the time delay accuracy using an oscilloscope every year. Replace it when the error exceeds ±15%.

3. **Troubleshooting**

- **Abnormal Indicator Light**: Check the power supply voltage (allowable fluctuation ±15%).

- **Contact Sticking**: Measure the load current and avoid exceeding the 8A peak value.

- **Time Delay Drift**: When the ambient temperature exceeds +50°C, it needs to be derated (for every 10°C increase, the service life is halved).

VIII. Official Resources and Purchase Information

- **Technical Documents**: The Schneider official website provides the **RE22R2QEMR Data Sheet** (Document Number: SDOC-RE22R2QEMR-01), which contains detailed circuit diagrams and wiring guidelines.

- **Purchase Channels**:

For further verification of parameters or obtaining customized solutions, it is recommended to provide specific application scenarios (such as load type, ambient temperature, installation method, etc.) to facilitate the recommendation of the optimal configuration.