Siemens Contactor 3RT6023-1AG20

Product description

The Siemens Contactor 3RT6023-1AG20 belongs to the Sirius 3RT6 series. It is suitable for motor start-stop control and circuit on-off operations in industrial automation systems. Below is a detailed analysis of its core parameters, functions, and application scenarios:

I. Core Technical Parameters

1. Rated Current and Voltage

Main Contacts: Under the AC-3 duty category, the rated operating current is 9A (corresponding to controlling a 4kW motor at 400V).

Coil Voltage: AC 110V (50/60Hz), with a typical voltage fluctuation range of 85%-110% of the rated value to ensure stable pull-in.

Conventional Enclosure Temperature Current (Ith): 10A, ensuring that the temperature rise does not exceed standard limits during long-term operation.

2. Mechanical and Electrical Life

Mechanical Life: Up to 10 million operations, suitable for scenarios requiring frequent operation.

Electrical Life: 500,000 operations (under AC-3 conditions). The contacts are made of silver alloy, featuring strong resistance to welding and wear.

3. Structure and Installation

Pole Number: 3 poles. The main contacts adopt a double-break structure, with an breaking capacity of 72A (8 times the rated current).

Installation Method: Supports 35mm DIN rail mounting or screw fixing. It has a compact size (45mm in width), saving space in control cabinets.

Protection Degree (IP Rating): IP20, which prevents finger access to live parts. However, it needs to be used with a cabinet to achieve a higher protection level.

4. Arc Extinction and Safety

Arc Extinction System: Built-in magnetic blowout arc chamber, which quickly extinguishes the arc generated when contacts open, reducing electromagnetic interference.

Isolation Voltage: The isolation voltage between the coil and main contacts reaches 400V, complying with the EN 60947-1 standard.

II. Functional Features and Applications

1. Control Compatibility

- It can be directly used with the relay output modules of Siemens S7-1200/1500 PLCs, or connected to transistor output modules via intermediate relays (attention should be paid to coil power matching).

- It supports remote control and is suitable for start-stop control of equipment such as automated production lines, pumps, and fans.

2. Modular Expansion

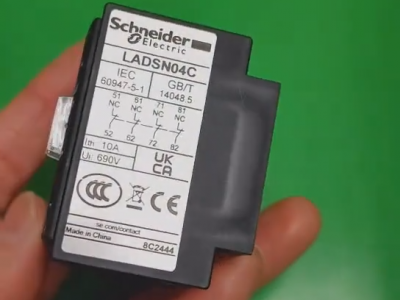

- Auxiliary contact modules (e.g., 1NO + 1NC) can be added to expand signal feedback functions and meet the requirements of complex logic control.

- It is compatible with Siemens 3RU6 series thermal overload relays, forming a motor protection circuit to achieve overload and phase-failure protection.

3. Environmental Adaptability

- Operating temperature range: -5℃ to +40℃, suitable for most industrial environments.

- It has an impulse voltage resistance of 6kV, capable of withstanding power grid surge interference.

III. Model Selection and Alternative Solutions

1. Reference for Alternative Models

- For higher current requirements, the 3RT6026-1AN20 (25A, AC220V) can be selected; for DC coils, it can be replaced with the 3RT6023-1BF40 (DC110V).

- The Siemens 3RT6 series is gradually replacing the 3TF series. For example, the 3TF33 (22A) can be replaced by the 3RT6026.

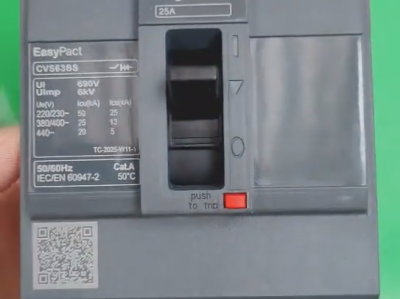

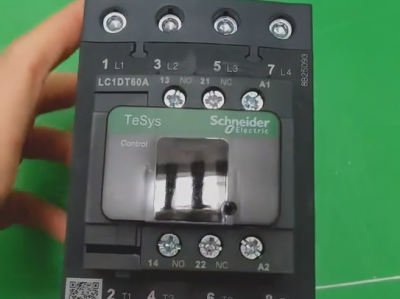

2. Competitor Comparison (Taking Schneider LC1D25M7C as an Example)

Current Rating: The LC1D25 has a current rating of 25A (AC-3), suitable for motors with higher power.

Coil Characteristics: The LC1D25 supports a voltage fluctuation range of 70%-120% and has a mechanical life of up to 20 million operations, but its price is slightly higher than that of the 3RT6023.

Modularity: Both models support auxiliary contact expansion, but the dust cover design of Schneider is more optimal.

IV. Usage Precautions

1. Coil Voltage Matching

- It is essential to ensure that the control circuit voltage is consistent with the rated coil voltage to avoid contactor malfunction or burnout caused by voltage deviation.

2. Contact Capacity Verification

- Under non-standard operating conditions such as AC-1 (non-inductive load) or AC-4 (frequent forward-reverse rotation), the contactor must be derated for use, and the model should be selected based on the actual current.

3. Maintenance Recommendations

- Regularly inspect the contact wear condition. Replace the contacts when their thickness is reduced to 1/3 of the initial value.

- Clean the dust inside the arc chamber to ensure that the arc extinction performance is not affected.

With its high reliability and flexible expandability, this contactor is widely used in fields such as elevators, textile machinery, and packaging equipment, making it a classic choice for industrial control.