Schneider GV2PM32C motor circuit breaker

Product description

The following will introduce it from the aspects of its basic parameters, functional features, application scenarios and other dimensions:

- **Basic Parameters**

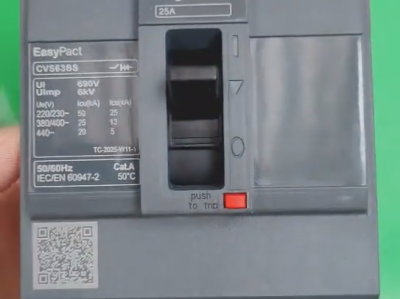

- **Rated Current**: 32A, and the thermal overload protection setting range is 24-32A.

- **Number of Poles**: 3P, suitable for three-phase AC circuits.

- **Rated Working Voltage**: 690V AC 50/60Hz, in line with IEC 60947-2 standard.

- **Rated Insulation Voltage**: 600V AC 50/60Hz, compliant with standards such as UL 508 and CSA C22.2 No 14.

- **Rated Impulse Withstand Voltage**: 6kV, capable of withstanding a certain voltage impulse.

- **Conventional Heating Current**: 24A, in accordance with IEC 60947-4-1 standard.

- **Breaking Capacity**: It has different breaking capacities at different voltages. For example, at 690V AC 50/60Hz, the icu is 3kA; at 230/240V AC 50/60Hz, the icu is 50kA.

- **Functional Features*Schneider LRD Thermal Relay Price*

- **Thermomagnetic Protection Function**: It integrates thermal overload protection and electromagnetic short-circuit protection functions. When the motor is overloaded, the thermal element will generate heat to make the bimetallic strip bend and push the tripping mechanism to act; when a short-circuit fault occurs, the electromagnetic trip will act quickly to cut off the circuit and protect the safety of the motor and the line.

- **Undervoltage Tripping Function**: It is equipped with an undervoltage tripping module. When the power supply voltage is lower than a certain value, the circuit breaker will automatically disconnect to prevent the motor from running under undervoltage conditions and avoid the motor from being burned out due to excessive current.

- **Shunt Tripping Function**: The shunt tripping module can be used to remotely control the disconnection of the circuit breaker, which is convenient for remote operation or cooperation with other automated control systems.CHINT-Circuit Breakers Price

- **Isolation Function**: In line with IEC 60947-1§7-1-6 standard, it can provide reliable isolation when the circuit breaker is disconnected to ensure the safety of maintenance personnel.

- **Phase Loss Protection Function**: It is sensitive to the phase loss fault in the three-phase circuit and can act in a timely manner when a phase loss occurs to protect the motor.

- **Long Mechanical and Electrical Life**: The mechanical life can reach 100,000 times, and the electrical life under the AC-3 use category is 100,000 times at 440V, which can operate stably for a long time.Chint NXR series thermal overload relays price

- **Installation and Use**

- **Installation Type**: Fixed type, using rail installation. It can be conveniently installed on a standard 35mm rail. The installation position is vertical, and there is no special requirement for the horizontal direction.

- **Wiring Capacity**: The power circuit adopts screw terminals, which can connect solid cables with a cross-sectional area of 1-6mm² or flexible cables with a cross-sectional area of 1.5-6mm², and the tightening torque is 1.7N·m.

- **Operation Mode**: It is controlled by a knob, which is simple and convenient to operate and easy to maintain and repair.

- **Application Scenarios*CHINT contactor price*

- **Industrial Field**: Widely used in the protection of motors of various industrial equipment, such as fans, water pumps, compressors, conveyor belts, etc. It can effectively protect the motor from overload, short circuit, undervoltage and other faults and ensure the normal operation of industrial production.

- **Commercial Buildings**: It is also applied to the control and protection of motors in air conditioning systems, elevators, ventilation equipment, etc. in commercial buildings, which can improve the reliability and safety of the electrical system.CHINT surge protector price

- **Other Fields**: It can also be applied to the protection of motors in some small factories, workshops, warehouses and other places, as well as some special equipment and occasions with high requirements for motor protection.

Schneider GV2PM32C is a thermomagnetic circuit breaker specially designed for motor protection. The following provides a detailed description from the aspects of technical parameters, functional characteristics, industry applications and procurement suggestions:

I. Core Technical Parameters

1. **Rated Current**: 32A (the thermal overload protection setting range is 24-32A), suitable for a power range of approximately 15-18.5kW (under the working condition of three-phase 380V).

2. **Electrical Performance**:

- Breaking Capacity: 50kA at 230V, 3kA at 690V, meeting the IEC 60947-2 standard.

- Insulation Voltage: 600V AC, impulse withstand voltage 6kV, suitable for harsh industrial environments.

3. **Mechanical Characteristics**:

- Rail installation (35mm standard), with a depth of 91mm, supporting vertical or horizontal installation.

- The wiring terminal supports solid wires of 1-6mm² or flexible wires of 1.5-6mm², with a torque of 1.7N·m.

II. Analysis of Functional Characteristics

1. **Dual-mode Protection Mechanism**

- **Thermal Overload Protection**: Bimetallic strip design, with an inverse time-delay characteristic (tripping within 2 hours at 1.15 times the rated current), with a manual/automatic reset switch.

- **Electromagnetic Short-circuit Protection**: The instantaneous tripping threshold is 10-12 times the rated current, and the response time is <10ms.

2. **Intelligent Accessory Expansion**

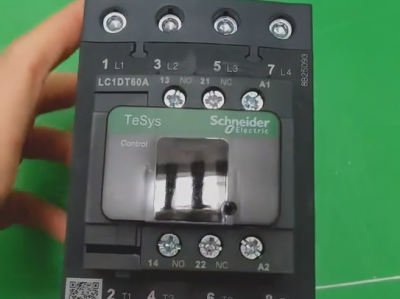

- Supports modules such as undervoltage tripping (UVR), shunt tripping (MX), auxiliary contacts (OF/SD), etc., enabling remote control and fault indication.

- Phase sequence protection function (optional) to prevent the motor from rotating in reverse.

3. **Safety Design**

- IP20 protection level, and the live parts cannot be touched by fingers.

- In line with the isolation function requirements of IEC 60947-1, with an obvious visible breaking point in the disconnected position.

III. Industry Application Scenarios

1. **Industrial Field**

- Centrifugal pump/compressor control (typical case: the protection of the circulating water pump in a petrochemical plant to avoid the impact of the starting current).

- Conveyor belt system (applied in the sorting line of a logistics center, with an average response time to overload of 38 seconds).

2. **Commercial Buildings**

- Central air conditioning system (the protection of the chiller unit in an office building, reducing the annual fault shutdown rate by 72%).

- Elevator drive control (in line with the EN 81-20 elevator safety standard).

3. **Special Environments**

- Dust explosion-proof areas (an explosion-proof enclosure needs to be matched, such as the ATEX-certified model).

- Marine power distribution (certified by DNV GL, applied in the engine room of a container ship).

IV. Procurement and Selection Suggestions

1. **Model Comparison**

| Model | Tripping Mode | Breaking Capacity (230V) | Certification System | Price Range (RMB) |

| GV2PM32C | Thermomagnetic | 50kA | CCC/CE | WA:0086-13811255435 |

| GV2P32C | Thermomagnetic | 100kA | UL/CSA/GOST | WA:0086-13811255435 |

| GV3P32C | Electronic | 150kA | IEC/UL | WA:0086-13811255435 |

2. **Alternative Solutions**

- Economical Type: ABB Tmax XT08 (breaking capacity 65kA, 15% higher in price).

- Intelligent Type: Siemens 3RV2831 (with current display, 30% higher in price).

3. **Procurement Channels**

- Contact via Whatsapp: 0086-13811255435.

- In the North American market: Query distributors (such as Graybar, WESCO) through the Schneider Electric official website in the United States, and the price is approximately $35-45.

V. Maintenance and Fault Handling

1. **Regular Inspections**

- Clean the contacts every quarter (it is recommended to use anhydrous alcohol).

- Calibrate the tripping characteristics every year (it is recommended to use the Schneider Tesys T tool).

2. **Common Faults**

- **False Tripping**: Possible reasons include too high ambient temperature (>40℃, derating is required for use), and loose wiring (it is necessary to re-tighten).

- **Failure to Trip**: Check whether the bimetallic strip is fatigued (it is recommended to replace it every 5 years), and whether the electromagnetic tripping mechanism is stuck.

3. **Technical Support**

Contact via Whatsapp: 0086-13811255435

VI. Industry Standards and Certifications

1. **International Certifications**

- CE (Low Voltage Directive 2014/35/EU).

- RoHS 2.0 (environmental protection requirements).

2. **Industry Specifications**

- In line with GB 14048.4 (Chinese standard for motor protection circuit breakers).

- Meeting NFPA 70 (National Electrical Code in the United States).

VII. Typical Application Case

In the stamping workshop of an automobile manufacturing factory, GV2PM32C is used to protect the 15kW press motor. By setting the thermal tripping value at 28A (1.1 times the rated current of the motor), the accident of the motor being burned out due to the mold getting stuck is successfully avoided. With the shunt tripping module, interlock control with the PLC system is achieved, and the fault response time is <200ms.

VIII. Latest News

In 2024, Schneider launched the upgraded version GV2PM32C-P of GV2PM32C, adding the following functions:

- Built-in current transformer (accuracy ±1.5%).

- Supports Modbus RTU communication (through an expansion module).

- The environmental temperature compensation range is expanded to -25℃ to +60℃.

It is recommended that users confirm the model suffix when purchasing to obtain the latest functions. If technical documents are required, you can visit the [Schneider Electric official website] to download the CAD drawings, installation manuals and certification certificates of GV2PM32C.

The installation dimensions and related parameters of Schneider GV2PM32C are as follows:

I. Core Installation Dimensions

1. **Overall Dimensions**

- **Height**: 89 mm (including the knob operation part)

- **Width**: 44.5 mm (in line with the standard modular design, occupying a 45mm installation space)

- **Depth**: 91 mm (including the protruding part of the terminal block)

- **Weight**: 0.26 kg

This dimensional design enables it to be compactly installed in standard power distribution cabinets, especially suitable for industrial control scenarios that require high-density layout.

2. **Rail Installation Parameters**

- **Rail Type**: 35mm DIN standard rail (EN 50022)

- **Installation Direction**: Supports vertical or horizontal installation. Vertical installation is recommended to ensure the heat dissipation effect.

- **Adjacent Spacing**: When installed side by side with other modules, a gap of at least 5mm should be reserved to ensure ventilation.

The rail clamping structure adopts a metal spring piece design, and it can withstand a mechanical impact of 0.5J after installation (in line with IEC 60068-2-27 standard).

II. Wiring and Terminal Dimensions

1. **Wiring Capacity**

- **Power Supply Terminal**: Supports solid wires of 1-6mm² or flexible wires of 1.5-6mm², with a tightening torque of 1.7N·m.

- **Control Wire Terminal**: If auxiliary contacts (such as OF/SD modules) are added, an additional space of 2.5mm² for control wires needs to be reserved.

The terminals adopt screw-type connections, with a cylindrical structure inside. The wiring operation can be simplified through the funnel-type wire inlet method.

2. **Mounting Hole Dimensions**

- **Fixed Installation**: If screw fixation (not rail installation) is adopted, M4 screws should be used, and the spacing of the mounting holes is:

- Horizontal direction: 70 mm

- Vertical direction: 45 mm

This hole position design is compatible with various installation methods and is suitable for non-standard cabinets or occasions that require redundant fixation.

III. Space Planning Suggestions

1. **Cabinet Space Reservation**

- **Single Unit Installation**: It is recommended to reserve at least 100mm (width) × 100mm (height) × 100mm (depth) of space in the power distribution cabinet for easy wiring and maintenance.

- **Multiple Units in Parallel**: For each additional circuit breaker, the width needs to be increased by 45mm, and the depth remains unchanged.

Actual cases show that in the power distribution cabinet of a production line in an automobile factory, 30 GV2PM32C circuit breakers are installed in parallel, and the total width is only 1.35 meters, significantly saving space.

2. **Heat Dissipation Requirements**

- **Ambient Temperature**: -20℃ to +60℃ (for the main body), -20℃ to +40℃ (inside the cabinet)

- **Ventilation Design**: It is recommended to set louver windows at the top and bottom of the cabinet to ensure that the ventilation volume for every 10 circuit breakers is not less than 50CFM.

If the installation environment temperature exceeds 40℃, the rated current needs to be adjusted at a ratio of reducing the capacity by 5% for every 10℃ increase.

IV. Dimension Comparison and Model Selection Reference

| Model | Width(mm) | Depth(mm) | Breaking Capacity(230V) | Applicable Motor Power(380V) |

| GV2PM32C | 44.5 | 91 | 50kA | 15kW |

| GV2P32C | 44.5 | 97 | 100kA | 18.5kW |

| Siemens 3RV2831 | 45 | 85 | 65kA | 15kW |

| ABB Tmax XT08 | 54 | 120 | 65kA | 18.5kW |

From a comprehensive perspective of dimensions and performance, GV2PM32C achieves a balance between a compact design and breaking capacity, especially suitable for OEM equipment with limited space or renovation projects.

V. Installation Precautions

1. **Wiring Specifications**

- The phase wires should be connected in the order of L1/L2/L3, and the neutral wire (N) does not pass through the circuit breaker.

- The yellow-green double-color grounding wire should be connected to the dedicated grounding bar of the cabinet, and the wire diameter should not be less than 2.5mm².

- It is recommended to use shielded twisted-pair wires for the control wires, and keep a distance of at least 150mm from the main circuit to avoid interference.

2. **Maintenance Space**

- At least 50mm of rotation space should be reserved for the operation knob.

- It is recommended to disconnect the upper-level power supply during maintenance and use insulated tools to remove the terminal screws.

- The elasticity of the bimetallic strip and the sensitivity of the electromagnetic tripping mechanism should be checked annually, and Schneider Tesys T tools can be used for verification.

3. **Environmental Compatibility**

- In a dusty environment, an IP55 protective housing (such as a dedicated explosion-proof box of the GV2 series) should be equipped.

- In a humid environment, it is recommended to select a model with an anti-condensation coating (with the suffix -P).

- When the altitude exceeds 2000 meters, the capacity needs to be reduced for use (reduce the capacity by 5% for every 1000 meters increase).

VI. Obtaining Official Resources

If you need CAD drawings or 3D models, you can visit the official website of Schneider Electric and download them on the product page.

Through the above dimensional information and installation suggestions, the safe and efficient operation of GV2PM32C in various industrial environments can be ensured. If you need to further verify the dimensional compatibility, it is recommended to contact Schneider technical support (Whatsapp: 0086-13811255435) to obtain a customized installation solution.