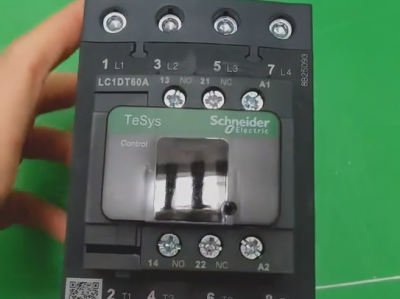

Schneider LC1D95 contactor

Product description

The Schneider LC1D95 contactor is a device commonly used in the field of industrial electrical control. The following introduces its basic parameters, product features, and application scope:

The Schneider LC1D95 contactor is a device commonly used in the field of industrial electrical control. The following introduces its basic parameters, product features, and application scope:

*Basic Parameters*Schneider BMH0702P17A2A*

- **Rated Current**

- Under the AC-3 usage category, the rated operating current is 95A, and the conventional heating current can reach 125A.

- **Rated Voltage*Schneider-MCCB-NSX250F-4P-250A *

- Suitable for circuits with alternating current of 50Hz or 60Hz. The rated insulation voltage is 690V, the rated operating voltage can reach up to 660V, and the coil control voltage usually has multiple options, such as AC 380V, 110V, etc.

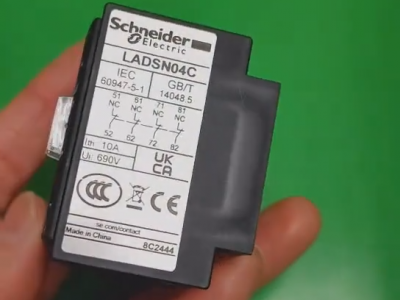

- **Auxiliary Contacts*Schneider Circuit Breakers Price *

- Generally comes with 1 normally open (NO) and 1 normally closed (NC) auxiliary contact, which can meet the needs of different control logics. The number of auxiliary contacts can be increased by installing an auxiliary contact group, with a maximum expansion to 6 contacts.

*Product Features*Chint's NB1-63DC series DC circuit breakers Price*

- **Long Service Life**

- Mechanical life up to 20 million times, and electrical life up to 2 million times, enabling stable operation for a long time, reducing replacement frequency, and lowering maintenance costs.

- **Strong Adaptability*Chint NXR series thermal overload relays price*

- Treated with "TH" protection, it can be used normally in humid and hot environments. When the coil control voltage fluctuates between 70%-120% of Uc, it does not affect the normal operation of the product, showing strong voltage adaptability.

- **Good Versatility*CHINT surge protector price*

- Equipped with a 50Hz-60Hz universal coil, it can adapt to power supply environments with different frequencies. The product complies with multiple international standards, such as IEC/EN 60947-4-1, GB14048.4, etc., with strong versatility and interchangeability.

- **Modular Design**

- Modules such as auxiliary contacts, on/off delay contacts, and mechanical locks can be attached to the product body, facilitating users to combine them according to actual needs. It can also be easily combined into reversible contactors, star-delta starters, etc., to meet different control requirements.

- **Convenient Installation**

- Can be installed via panel mounting or DIN rail mounting. The wiring terminals are IP20 finger-safe type, with good safety, and support multiple wiring methods, such as screw connection, spring terminals, Everlink terminals, etc.

*Working Principle**

The LC1D95 contactor is mainly composed of an electromagnetic system, a contact system, an arc extinguishing system, etc. When the coil of the electromagnetic system is energized, it generates a magnetic field, attracting the armature to act, changing the states of the main contacts and auxiliary contacts of the contact system, thereby realizing the switching on or off of the circuit. When the contacts break the circuit, the arc extinguishing system ensures reliable extinguishing of the generated arc, reducing arc damage to the contacts.

*Application Scope**

- **Motor Control**

- Commonly used to control various types of motors, such as three-phase asynchronous motors, etc., to achieve remote starting, stopping, forward and reverse rotation control of motors. It can also be used in conjunction with thermal relays to provide overload protection for motors.

- **Industrial Automation Systems**

- In the fields of industrial automation production lines, mechanical equipment, etc., it can be used to control the on/off of various electrical equipment to realize the control and monitoring of automated production processes, such as controlling the operation of conveyor belts, the opening and closing of valves, etc.

- **Power Distribution Systems**

- In power distribution systems, it can be used to switch on and off circuits to achieve power distribution and control. For example, as the main control component in distribution boxes and switchgear, it controls and protects the power of different branches.

*Precautions**

- **Selection Notes**

- When selecting the model, it is necessary to choose the appropriate contactor model and specification according to actual load current, voltage, usage environment, and other factors to ensure it can meet the needs of practical applications.

- **Installation Requirements**

- Pay attention to the flatness and perpendicularity of the installation position to avoid vibration or looseness of the contactor during operation. At the same time, ensure firm wiring to avoid virtual connections, which may cause problems such as heating or poor contact.

- **Maintenance**

- Regularly inspect and maintain the contactor, clean the dust and oxides on the contact surface, and check the wear condition of the contacts. If severe wear is found, replace the contacts in a timely manner to ensure the performance and reliability of the contactor.

Working Principle of Schneider LC1D95 Contactor

The working principle of the Schneider LC1D95 contactor realizes the on/off control of the circuit and arc protection through the collaborative effect of the electromagnetic system, contact system, and arc extinguishing system. The details are as follows:

**I. Core Components**

1. **Electromagnetic System**

- Includes the coil, iron core (static iron core), and armature (movable iron core), serving as the power source of the contactor.

2. **Contact System**

- **Main Contacts**: Used to switch on or off the main circuit, usually 3 pairs of normally open contacts, made of silver alloy with good electrical conductivity and wear resistance.

- **Auxiliary Contacts**: Used for control circuits (such as PLC signal feedback, interlock control), including NO/NC contacts (default 1 NO + 1 NC, expandable).

3. **Arc Extinguishing System**

- Adopts a grid-type arc extinguishing structure composed of metal grids, used to quickly extinguish the arc generated when the contacts are disconnected.

*II. Analysis of the Working Process**

#### **1. When the Coil is Energized (Circuit On)**

- **Electromagnetic Suction**: After the coil is connected to the rated voltage (such as AC 380V, 110V, etc.), an electromagnetic field is generated, and the static iron core attracts the armature.

- **Contact Action**: The armature moves toward the static iron core against the counterforce of the spring, driving the main contacts and auxiliary contacts to act synchronously:

- The main contacts change from "open" to "closed", switching on the main circuit (such as the motor power supply circuit).

- The auxiliary NO contacts close, and the NC contacts open, realizing signal transmission in the control circuit (such as indicator light on, interlock logic triggering).

*2. When the Coil is De-energized (Circuit Off)**

- **Electromagnetic Disappearance**: After the coil is de-energized, the magnetic field disappears, and the armature is released under the action of the return spring.

- **Contact Reset**: The main contacts and auxiliary contacts return to their initial states:

- The main contacts change from "closed" to "open", cutting off the main circuit.

- The auxiliary contacts reset (NO contacts open, NC contacts close), and the control circuit signal is interrupted.

*III. Arc Extinguishing Principle**

When the main contacts break a large current (such as during motor start/stop), a high-temperature arc is generated between the contacts. The arc extinguishing system extinguishes the arc through the following mechanisms:

1. **Arc Entry into the Grid**: The arc enters the gap of the metal grid under the action of electromagnetic force and thermal airflow.

2. **Arc Segmentation and Cooling**: The grid divides the long arc into multiple short arcs, while absorbing the arc heat, rapidly reducing the arc temperature, accelerating ion recombination, and finally extinguishing the arc to protect the contacts from ablation.

*IV. Key Characteristics and Working Logic**

- **Voltage Adaptability**: When the coil control voltage fluctuates within the range of 70%-120% of the rated value, it can still reliably suck in and release, avoiding contact jitter or misoperation caused by voltage fluctuations.

- **Mechanical and Electrical Life**: The mechanical life reaches 20 million times (armature suction/release cycles), and the electrical life reaches 2 million times (main contact on/off of large current), relying on the stability of the electromagnetic system and the efficiency of the arc extinguishing system.

- **Modular Expansion**: By adding auxiliary contacts, delay modules, etc., it can flexibly adapt to complex control logics (such as star-delta starting, reversible control), but the core of the working principle still relies on electromagnetic-driven contact action.

*Conclusion**

The Schneider LC1D95 contactor is essentially an "electromagnetically driven switching element". Through the conversion of electrical-magnetic-mechanical actions, it realizes the on/off control of the main circuit. At the same time, it uses an arc extinguishing system to ensure safety when breaking large currents. Its design balances reliability, durability, and expandability in industrial scenarios.