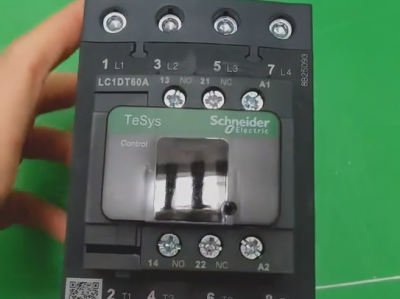

Schneider LC1F500 AC contactor

Product description

The Schneider LC1F500 AC contactor is a high-performance device specifically designed for industrial motor control, suitable for high-current scenarios. The detailed analysis of its core information is as follows:

*I. Core Parameters and Performance*Schneider-MCCB-NSX250F-4P-250A*

1. **Rated Current and Voltage**

- **Main Circuit**: The rated operating current is 500A (at 380V under the AC-3 usage category), and it can withstand short-term overloads of up to 700A. The main contacts are made of silver-tungsten alloy, which features excellent electrical conductivity and arc erosion resistance to ensure long-term reliable operation.

- **Coil Voltage**: Multiple options are available, including 220V (model suffix M7), 380V (Q7), 110V (F7), etc., to adapt to different control voltage requirements.

2. **Contact Configuration*Schneider Circuit Breakers Price*

- **Main Contacts**: Three normally open main contacts can control three-phase motor circuits, supporting complex applications such as star-delta starting and reversible control.

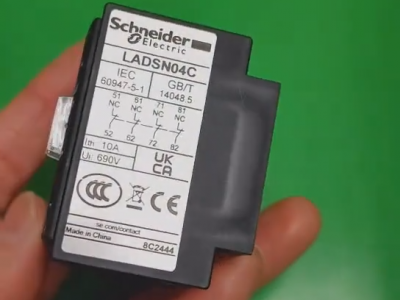

- **Auxiliary Contacts**: The standard configuration is 1 normally open + 1 normally closed (type 11), but it can be modularly expanded to up to 4 pairs of auxiliary contacts (e.g., the LADC22 module provides 2 normally open + 2 normally closed) to meet diverse control logic needs.

3. **Mechanical and Electrical Life*Chint's NB1-63DC series DC circuit breakers Price*

- **Mechanical Life**: It can reach over 10 million operations under no-load conditions, verifying the durability of its mechanical structure.

- **Electrical Life**: Approximately 1 million operations under rated load. The silver-oxide-tin contact material effectively reduces arc loss and extends the life of loaded operations.

*II. Design Features and Installation*Chint NXR series thermal overload relays price*

1. **Structure and Protection**

- **Arc Extinguishing System**: Equipped with a large-capacity arc chute, which can quickly extinguish the arc generated during breaking, protect the contacts, and reduce electromagnetic interference.

- **Protection Level**: Although not explicitly marked, it meets industrial environment requirements and can withstand a certain degree of dust and liquid splashing (refer to the IP54 standard of similar products).

2. **Installation Methods*CHINT surge protector price*

- Supports installation on 35mm or 75mm standard rails, and can also be fixed with screws, flexibly adapting to different control cabinet layouts.

3. **Certifications and Compliance**

- **Domestic Certification**: Passed CCC certification, conforming to Chinese low-voltage electrical standards.

- **International Certification**: Imported models (such as LC1F500M7) may have UL certification (confirm the specific model suffix), suitable for export equipment.

*III. Application Scenarios and Alternatives**

1. **Typical Applications**

- Suitable for frequent starting and control of high-power motors such as pumps, fans, and compressors, especially performing excellently in industries like metallurgy, chemical engineering, and water treatment.

- Can be combined with thermal relays (such as the LRD series) to form magnetic starters, providing overload protection.

2. **Alternative Models and Compatibility**

- **New Model Recommendation**: The LC1G500KUEN, as an alternative model, adopts the Giga series design, further optimizing reliability and maintainability. It supports wide voltage input (100–250V) and is compatible with the installation dimensions of the original LC1F500M7.

- **Notes**: When replacing, confirm whether the coil voltage and auxiliary contact configuration match, and some functional modules may need to be reselected.

*IV. Selection and Maintenance Suggestions**

1. **Selection Key Points**

- Choose the current rating according to the motor power and duty cycle (e.g., 500A is suitable for approximately 250kW motors).

- Prioritize 50/60Hz universal coils (such as the M7 suffix) to adapt to power grid frequencies in different regions.

2. **Maintenance Tips**

- Regularly inspect the wear condition of the contacts. Replace the contact module when the over-travel is less than 50% of the initial value.

- Clean the carbon deposits inside the arc chute to ensure good heat dissipation and avoid performance degradation due to overheating.

*V. Market and Procurement Information**

- **Supply Status**: The LC1F500 is still in production, but some regions may shift to the LC1G series. It is recommended to confirm inventory through Schneider's official channels.

- **Price Range**: Depending on the configuration, the market reference price is between 5,000 and 8,000 RMB, with imported models slightly higher than domestic ones.

With its high reliability and flexible configuration, the Schneider LC1F500 has become a classic choice for industrial motor control. For higher performance or more advanced digital functions, consider upgrading to the TeSys Giga series (such as LC1G500KUEN) to meet the needs of future Industry 4.0.

The mechanical and electrical life of the Schneider LC1F500 AC contactor follows clear technical specifications under different operating conditions, with specific parameters as follows:

*I. Mechanical Life**

According to Schneider's official technical data and authoritative sources, the **mechanical life of the LC1F500 under no-load operation (main circuit de-energized) is 10 million operations**. This indicator verifies the durability of the contactor's mechanical structure, including the long-term reliability of key components such as the contact support, springs, and iron core. For example, the RS official website clearly states its mechanical durability as 10 million cycles, and authorized distributors like Graybar also confirm this parameter.

*II. Electrical Life**

1. **AC-3 Usage Category (Motor Control)**

Under the AC-3 usage category (typically used for starting and controlling squirrel-cage motors), the **electrical life of the LC1F500 is 1 million operations**. This data is based on the following test conditions:

- Rated operating voltage: 380V AC (corresponding to a motor power of approximately 250kW)

- Rated operating current: 500A

- Operation frequency: ≤1,200 times/hour

2. **Other Usage Categories (e.g., AC-4)**

For the AC-4 usage category (frequent operations under high-inductive loads or motor堵转 (locked-rotor) conditions), the electrical life is significantly reduced. For example, the electrical life of the LC1-D series contactors under the AC-4 category is only 150,000 operations (for 40–65A models), but as a high-power model, the AC-4 life of the LC1F500 should refer to the specific technical manual. Currently, public information does not specify the AC-4 life data of the LC1F500, so it is recommended to consult Schneider technical support for high-impact load scenarios.

*III. Core Influencing Factors**

1. **Contact Material and Design**

The main contacts of the LC1F500 are made of silver-tungsten alloy, which has strong arc erosion resistance. In AC-3 operations, silver-oxide-tin contacts can effectively reduce contact wear, while silver-tungsten alloy is more suitable for high-current breaking.

2. **Environment and Maintenance**

- **Temperature**: When the ambient temperature exceeds 55°C, the electrical life may decrease (refer to the temperature derating curve in Summary 3).

- **Cleanliness**: Carbon deposits in the arc chute will affect heat dissipation and need to be regularly cleaned to avoid overheating.

- **Over-travel Monitoring**: Replace the contact module when the contact over-travel is less than 50% of the initial value to maintain performance.

*IV. Data Validation and Reliability**

- **Third-Party Certifications**: The LC1F500 has passed CCC, UL, CSA, etc., and its life data complies with IEC 60947-4-1 standards.

- **Practical Application Feedback**: In long-term operation in industries such as metallurgy and chemical engineering, the life performance of the LC1F500 is consistent with laboratory data, especially stable in AC-3 loads like pumps and fans.

*V. Notes**

1. **Model Differences**: Some sources (such as Summary 15) mention a "mechanical life of 1 million operations," which may be due to model confusion or typographical errors. The correct mechanical life of the LC1F500 should be 10 million operations, while 1 million operations are more in line with the parameters of the small-current LC1-D series contactors.

2. **Alternative Model Reference**: The new model LC1G500KUEN (TeSys Giga series) has a mechanical life increased to 20 million operations and an electrical life of 2 million operations, and it is compatible with the original installation dimensions, suitable for scenarios pursuing higher performance.

*Summary**

The Schneider LC1F500 has a **mechanical life of 10 million operations and an electrical life of 1 million operations under the AC-3 usage category**, achieving a balance of high reliability and long life in industrial motor control. In practical applications, it is necessary to combine the load type, environmental conditions, and maintenance strategies to maximize equipment efficiency.